Wear types of milling cutters

Wear type

Actions

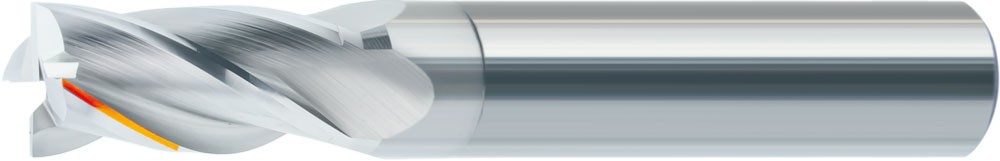

Flank wear

wear between the workpiece and the flanks

✓ Reduce cutting speed (Vc)

✓ Increase feed rate (fz)

✓ Increase coolant pressure

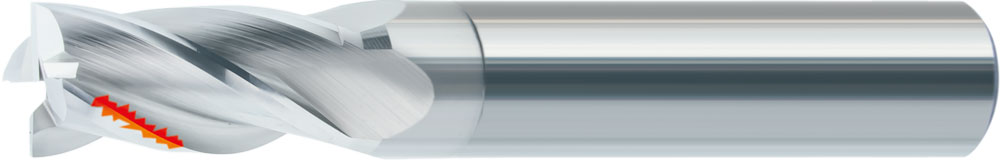

Built-up edge

Parts of the material adhere to the cutting edge due to welding

✓ Increase cutting speed (Vc)

✓ Reduce feed rate (fz)

✓ Increase coolant pressure

✓ Use tool with a sharper cutting edge

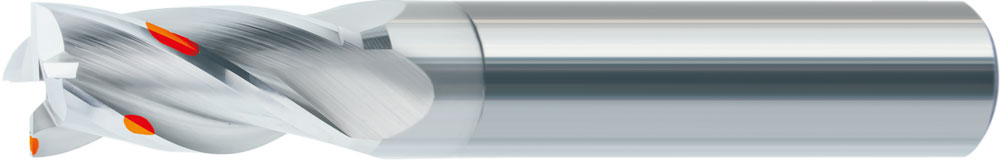

Breakouts (along the cutting edge)

are caused by vibrations, chip jams, thermal cracks and excessive brittleness of the material

✓ Reduce cutting speed (Vc)

✓ Increase feed rate (fz)

✓ Increase coolant pressure

✓ Use tool with edge preparation e.g. VSO

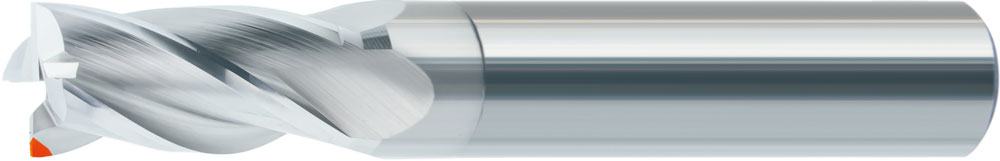

Plastic deformation

due to too high temperatures and too high mechanical stresses

✓ Reduce cutting speed (Vc)

✓ Reduce feed rate (fn)

✓ Increase coolant pressure

Wear types of drills

Wear type

Actions

Flank wear

wear between the workpiece and the flanks

✓ Reduce cutting speed (Vc)

✓ Increase feed rate (fn)

✓ Increase coolant pressure

Built-up edge

Parts of the material adhere to the cutting edge due to welding

✓ Increase cutting speed (Vc)

✓ Increase feed rate (fn)

✓ Increase coolant pressure

Breakouts (along the cutting edge)

are caused by vibrations, chip jams, thermal cracks and excessive brittleness of the material

✓ Change tools in time and have them

reconditioned (WEDCO Service)

✓ Check tool clamping (vibrations)

✓ Check tool concentricity

✓ Reduce cutting speed (Vc)

✓ Reduce feed rate (fn)

Plastic deformation

due to too high temperatures and too high mechanical stresses

✓ Reduce feed rate (fn)

✓ Reduce cutting speed (Vc)

✓ Increase coolant pressure

General hints

– Check concentricity when tool is clamped

– Check workpiece clamping and cleanliness of clamping surfaces

– Check tool clamping

– Correct choice of tools (pay attention to the ISO material groups when selecting tools)

Our experts will be happy to answer any further questions