✔

UNSURPASSED QUALITY AND ACCURACY

✔

DEVELOPMENT AND PRODUCTION FROM JUST 2 PIECES

✔

SHORTEST LEAD TIMES IN THE INDUSTRY

Our customers are professionals. Nevertheless, they benefit greatly from our knowhow – especially when it comes to our expertise in developing optimal machining strategies and suitable custom-made tools for challenging machining tasks in the shortest possible time.

The WEDCO range of catalog tools offers suitable solutions for almost all applications. However, the efficiency of production can often be further increased by using special tools: processing steps can be saved, productivity optimized, and tool costs reduced. As part of the component development, we provide a basis for deciding whether a custom-made tool enables more economical production. The WEDCO team supports you in the conception of the optimal machining strategy and develops a solid carbide special tool optimized for the respective application. The fact that this custom-made product is completely developed and produced in our factory is a great factor for our success. Only this high level of vertical integration enables us to react so quickly. We work with you and for you to develop a solution that is worthwhile in any case.

Component development, tool development, production, and coating from a single source and at one location: This is the only way we can deliver top-quality custom-made products in record time.

In terms of unit costs, special tools are at first glance significantly more expensive than conventional standard catalog tools. However, they often offer considerable potential for cutting costs. Because above all, complex processes that require the combination of several processing steps and several tools can be implemented much more efficiently and ultimately more cost-effectively with process-specific special solutions. Let’s take a look at your current machining process together, you will be surprised!

THEREFORE PROCESS OPTIMISATION WITH WEDCO

- Speed:Nobody beats us there. You will be surprised at how quickly your request is processed by us and you will receive your custom-made milling cutter or drill in record time, because time is a decisive factor in production.

- Component development – WEDCO offers the perfect advice. On request, our technologists will take a non-binding look at your application on site and work with you to develop the perfect machining strategy.

- Advice, development and production come from a single source at WEDCO. The advantages are clear: 100% Made in Austria with the highest quality, faithfulness to the concept and fastest delivery.

- The same high material quality and precision as with our catalog tools is guaranteed. Special tools are manufactured on the same 5-axis machining centers as the tools from our standard production with more than 50,000 units per month.

- Reliability through process monitorin and documentation of the entire special tool production.

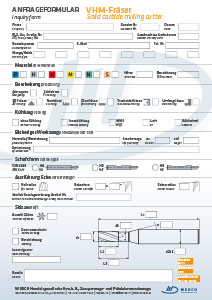

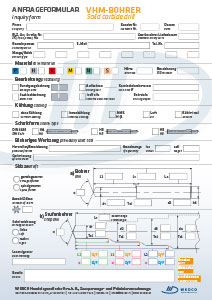

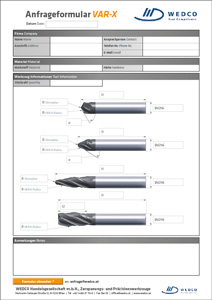

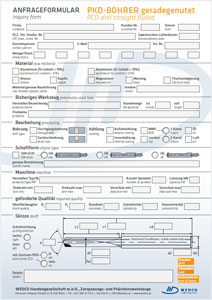

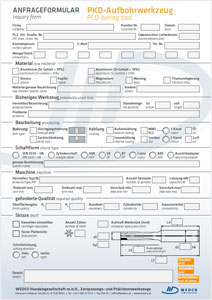

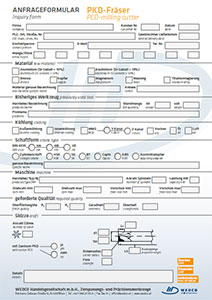

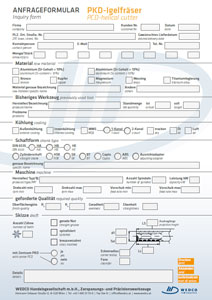

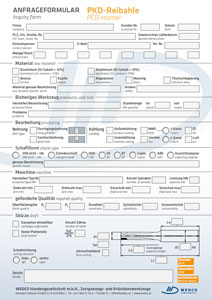

Sie haben SCHON genaue Vorstellungen oder Daten?

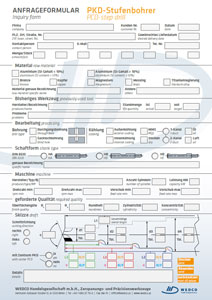

NUtzen Sie unsere detaillierten Anfrageformulare für Sonderanfertigungen:

VHM Werkzeuge

PKD Werkzeuge