Horn offers a broad standard range for the reliable milling of aluminium, non-ferrous metals and engineering plastics – available immediately from stock.

Technological diversity and quality: From simple PCD end mills to modular combination tools – Horn focuses on economical solutions with high flexibility, strict quality standards and high-performance PCD cutting materials.

Technological diversity and quality:

From simple PCD end mills to modular combination tools – Horn focuses on economical solutions with high flexibility, strict quality standards and high-performance PCD cutting materials.

Optimised aluminium machining:

By correctly matching the tool, cutting parameters and coolant, typical machining problems such as galling, chip flow interruption or tool wear can be avoided.

PCD-Milling

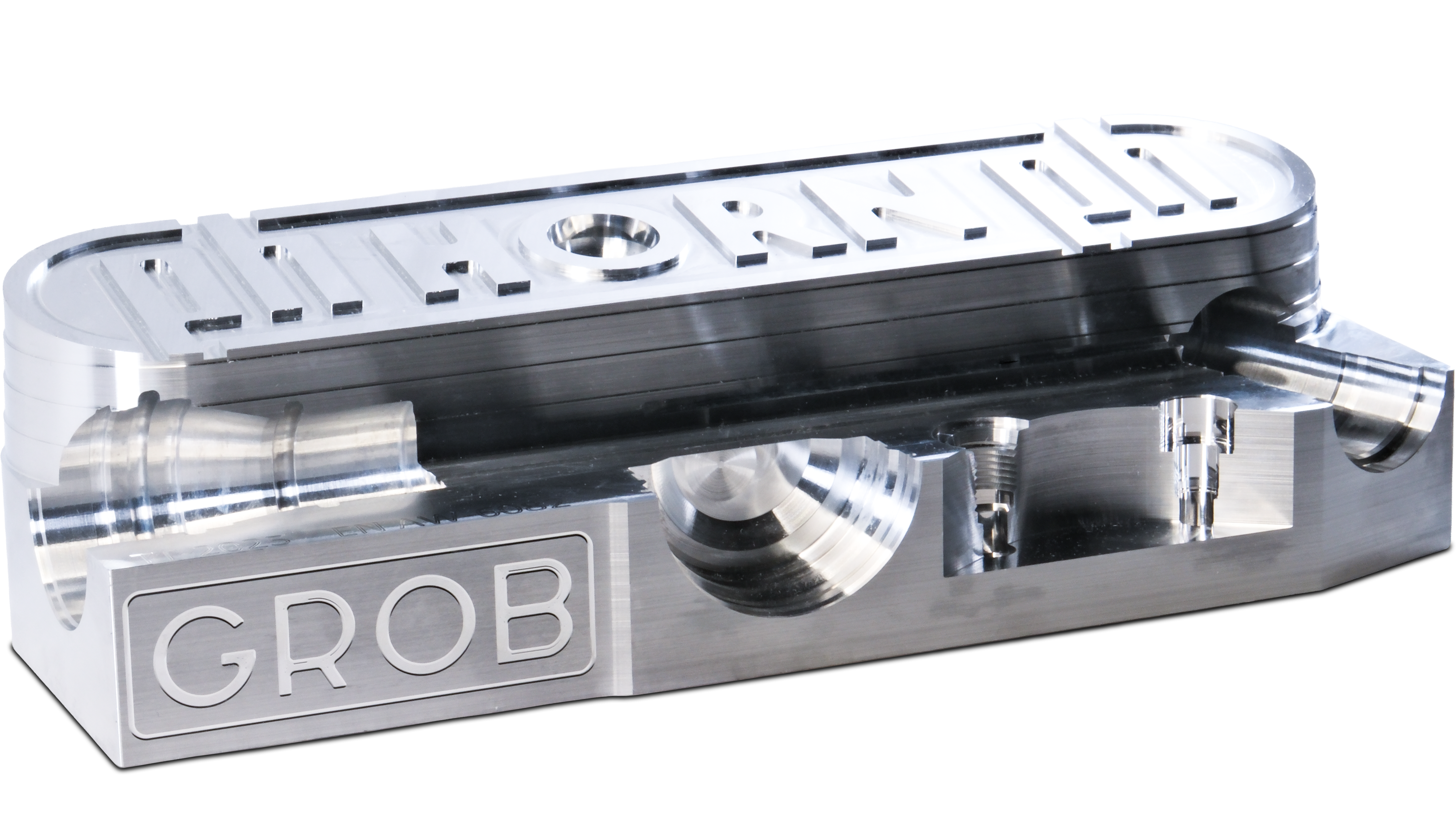

With over 30 years of experience in the development and production of precision tools from ultra-hard cutting materials, Horn offers a comprehensive range of PCD milling tools for productive machining of aluminium. During this time, Horn has proven itself in numerous industries – and has thus become a key partner in the field of PCD tools. The new PCD milling programme is part of this long-standing development and complements the portfolio. Based on market experience and customer requirements, Horn has developed a complete standard range of milling tools. The diverse standard programme of the DM 20 to DM 90 series is well suited to reliable machining of aluminium, non-ferrous metals and technical plastics. With an emphasis on conserving resources, coordinated cutting lengths and tool designs, the tools are available from stock.

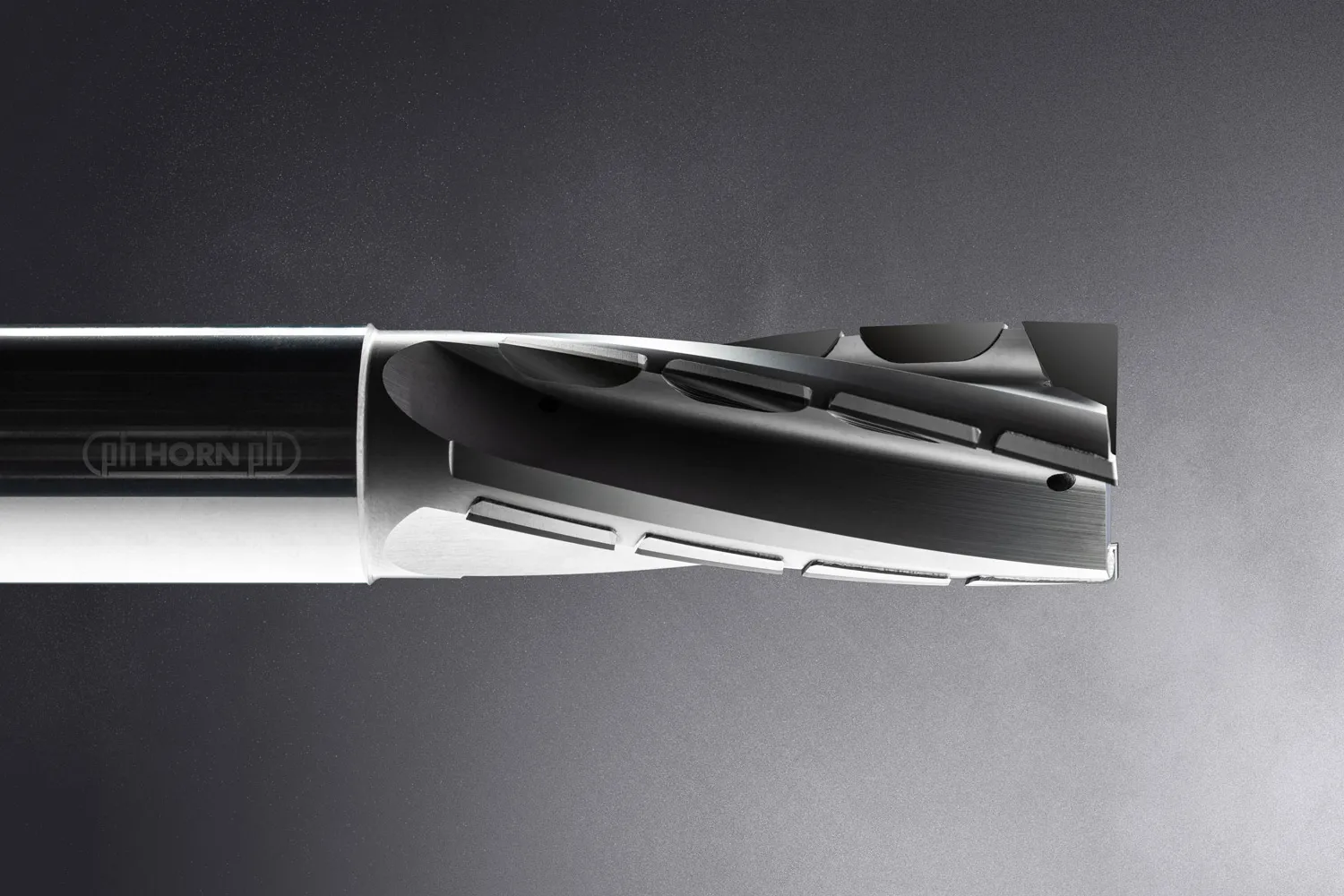

In this product programme, Horn offers a wide range of standard and special tools from simple PCD end mills to complex and modular combination tools. The driving force is a focus on economical solutions offering high productivity, combined with Horn technology, flexibility and reliability. Horn’s high-performance PCD cutting material is composed of a sophisticated mixture of diamond grains of different sizes. As the volume fraction of diamond increases, so do the effective hardness, toughness and cutting edge quality. Strict quality standards and their control are a matter of course and ensure outstanding performance.

Machining aluminium

The tensile strength, elongation, hardness and strength of aluminium can be influenced by alloying elements such as silicon, magnesium, copper, zinc and manganese. The material can soften during machining due to the heat generated, stick to the cutting tool and even destroy it due to disrupted chip flow. It is therefore important that the material and cutting parameters are properly matched. It depends on the aluminium alloy, the cutting tool, the feed rate and speed, as well as the type and quantity of coolant.

Aluminium – a versatile material used in all sectors of industry. With its new PCD milling range, Horn offers a broad portfolio of optimised tools for economically machining this light metal.

Horn tools for machining aluminium

The most important features of Horn’s wide range of standard and special tools are special chip control geometries with sharp cutting edges, polished cutting surfaces, and coatings having excellent sliding properties due to aluminium’s strong tendency to adhere. Carbide inserts for grooving are also peripherally ground to ensure an extremely sharp cutting edge. For machining aluminium alloys with a high silicon content, the inserts are coated. The portfolio includes coated and uncoated inserted tools for circular interpolation milling and solid carbide cutters for milling. Due to the large volume of chips resulting from the high cutting data, single-edged milling cutters with large chip removal rates are also available. Ultra-hard cutting materials such as PCD and CVD-D with precision laser-cut edges are available for long service life or more complex work. MCD-tipped tools are used, for example, for high-polish machining of mirrors or aluminium blow moulds.

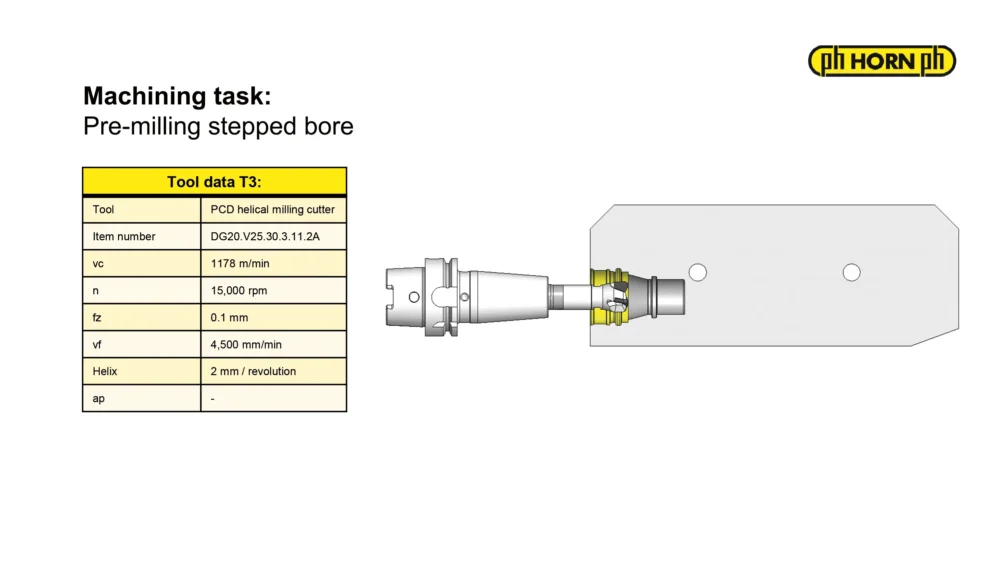

DG modular interchangeable head milling system

With well over 1,000 customised solutions and numerous standard variants, HORN is demonstrating an economical and resource-saving tool solution with the DG modular interchangeable head milling system. With the new tool generation, Horn has optimised the interface between the cutting head and shank for greater versatility, stability and higher changeover precision. This is made possible by the new, solid carbide monoblock design of the replaceable head. It means that the interface and the desired cutting edge shape are precision ground from a carbide blank. The system achieves high precision through a guide pin, a precision trapezoidal thread and a taper/flat contact. The changeover accuracy is in the µ range. This reduces the set-up time and cuts production costs. The modular design allows quick changeover to a different cutting insert and the use of customised special solutions.

Horn stocks the milling system as standard in diameters of 10 mm (0.394“), 12 mm (0.472“), 16 mm (0.630“), 20 mm (0.787“) and 25 mm (0.984“). In addition, numerous cutting edge shapes for the most common machining tasks are available from stock. The user can choose an interchangeable head with a cutting edge length of either 0.5 x diameter or 1 x diameter. The cutter shanks are available in solid carbide and steel versions. All types have an internal coolant supply. For economical and productive machining of material groups P and K, Horn offers the new grade RC4P.

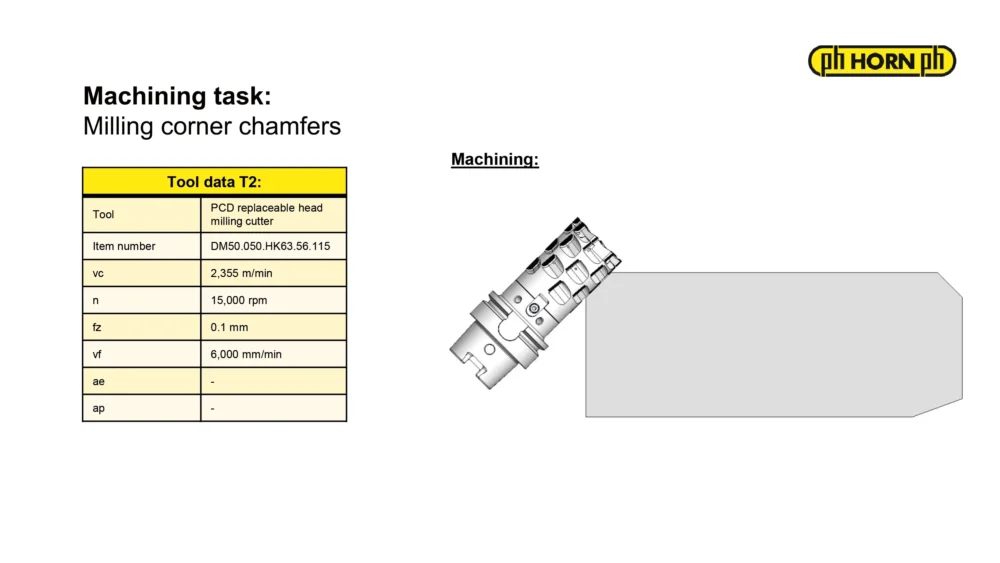

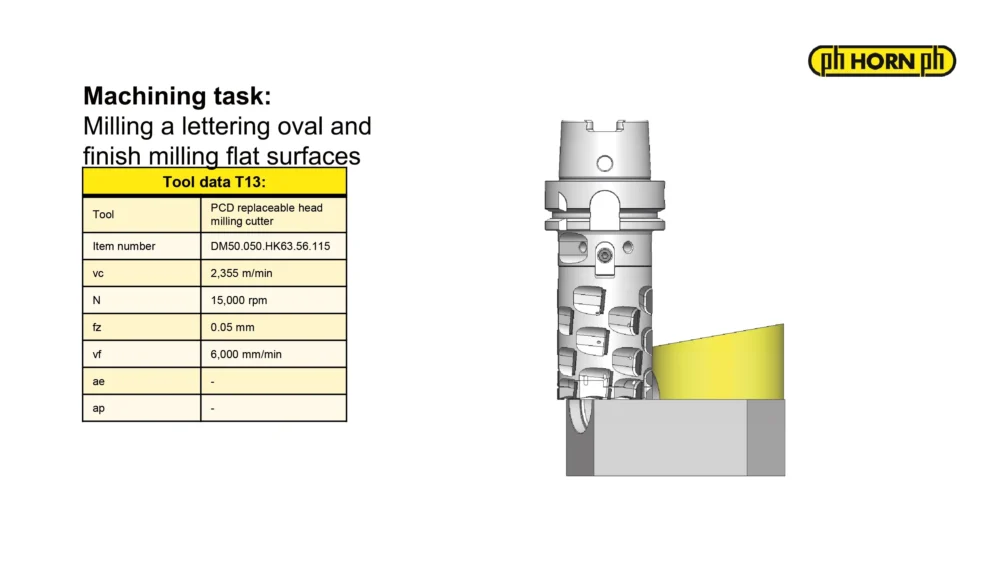

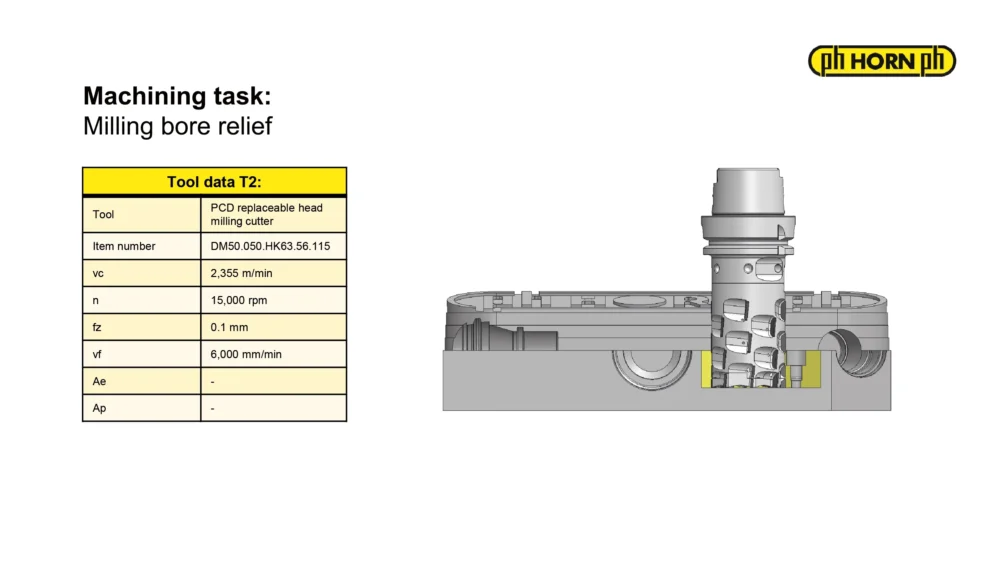

PCD exchangeable head milling cutter DM50

The new PCD milling programme from Horn includes the DM 50 series, a replaceable head milling system for economical machining of aluminium that is particularly suitable for universal applications including those where the cycle time is critical.

With the DM50 series, HORN offers a tool concept that is a well thought out solution in terms of wear, flexibility and cost effectiveness, especially for universal applications and those that require optimal cycle times. The main wear zone of the head and the inserts can be replaced, as can an intermediate sleeve that enables different cutting heights. The system therefore offers a tool solution that can be flexibly customised to any application, while at the same time focusing on operating and service costs. Thanks to its high level of versatility, the tool system can be converted quickly to different corner radii and corner chamfers with the desired cutting height. The combination of inserts on the face and periphery in a 2:1 ratio is tailored to different application requirements and milling techniques. Precise positioning on changeover without any offset guarantees accurate milling results. The design, with an emphasis on the axis angle, enables soft cutting and high surface quality.

The replaceable head milling cutters round off the wide range of standard and special tools in HORN’s portfolio of ultra-hard cutting materials, making the tool manufacturer an important partner in the field of PCD tools.

New PCD milling programme – face mill

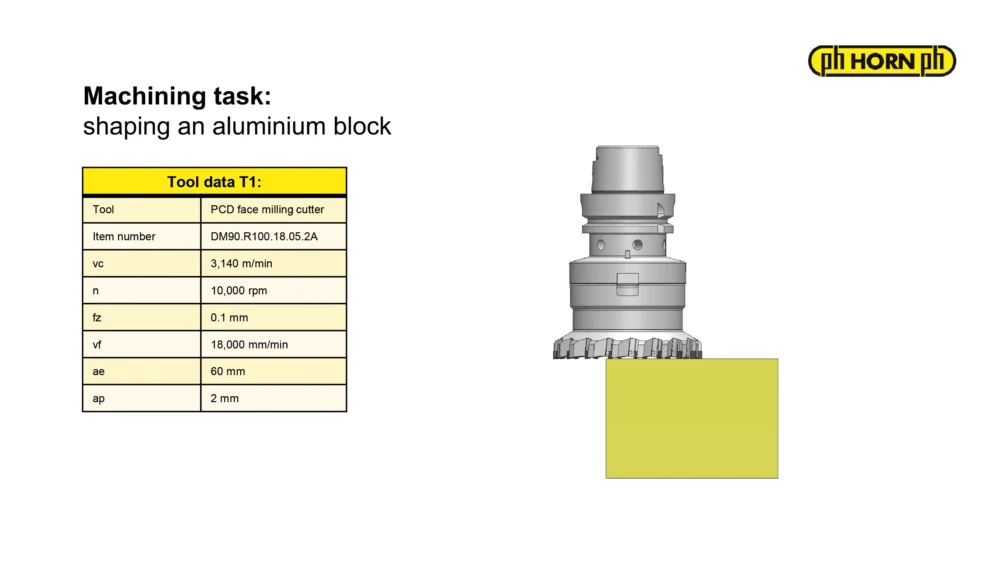

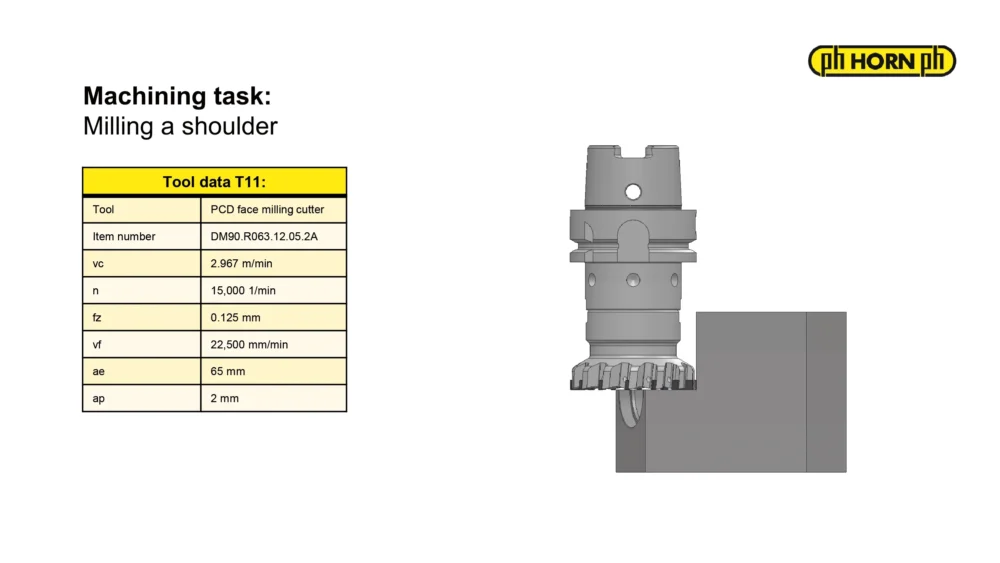

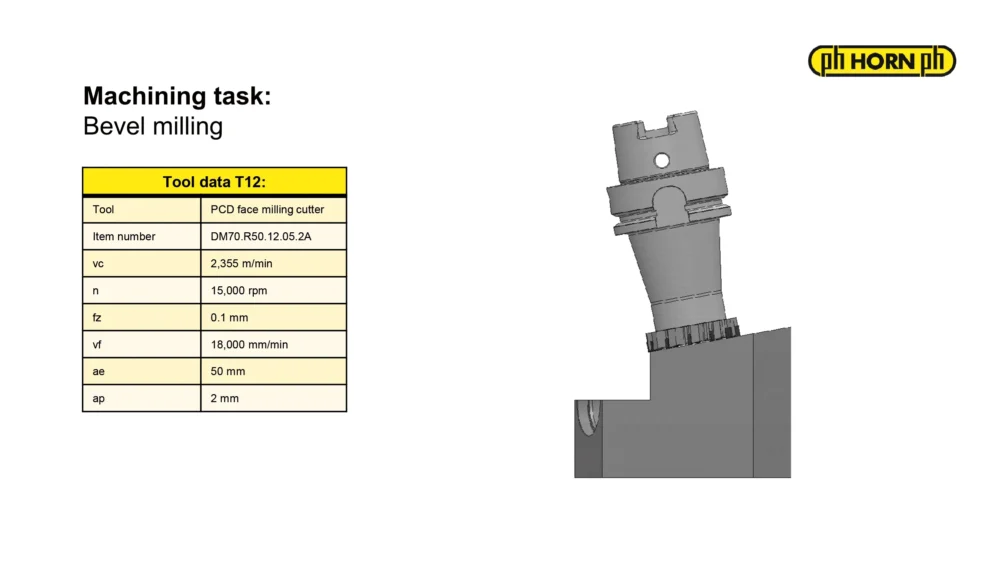

As part of its new PCD milling programme, Horn has developed the DM70 and DM90 series, which is specially designed for face milling and shoulder milling. The focus is on high efficiency milling and surface quality as well as burr-free milling.

DM70

Horn developed the DM70 series especially for face milling. The system enables high efficiency milling and good surface quality when using small diameter tools. The precise face and taper contact interface guarantees axial run-out to within microns. The simple and quick replacement of the PCD-tipped milling cutter onto a carbide body is suitable for lean production processes and automated production systems. The carbide body also offers high stability and guarantees a long service life, even when the inserts are re-tipped several times. The series is ideal for stable milling as well as face milling operations in deep structural components due to the availability of large and small diameter variants, as well as a short and a long HSK63-A holder. The tools offer reliable cooling with a sophisticated, screw-mounted coolant distribution system on the face.

DM90

From face milling or shoulder milling of die-cast aluminium components to the machining of engine or housing components and even the face milling of surfaces of various non-ferrous metals, burr-free machining is essential. Accordingly, PCD-tipped inserts are the benchmark. The DM90 series is specially designed to meet these requirements and deliver high performance. It is available with long or short flutes in diameters from 50 mm (1.968“) to 125 mm (4.921“). HORN offers the appropriate tool for these applications, without the need for time-consuming presetting of the inserts. The series is notable for its extremely smooth running and axial run-out accuracy to within microns. Whether for roughing cuts up to ap = 4 mm (0.157“) or for finishing cuts, the system achieves surface finishes of better than Rz 4 µm (0.000157“).

Cost-effectiveness and productivity combined with Horn technology, high flexibility and reliability are offered by the extensive range of Horn tools in the field of ultra-hard cutting materials. The face milling cutters of the DM70 and DM90 series complement the portfolio for reliable aluminium machining in combination with five PCD end milling cutter types and an exchangeable head milling system.

New PCD milling programme – end mills

The new PCD milling programme from Paul Horn GmbH, with a focus on productive and reliable machining of aluminium, includes a wide range of standard and special tools from end mills to complex and modular combination tools. The PCD end mills in the DM20–DM33 series are universal all-rounders and, with their respective technical specifications, are suitable for a wide range of applications.

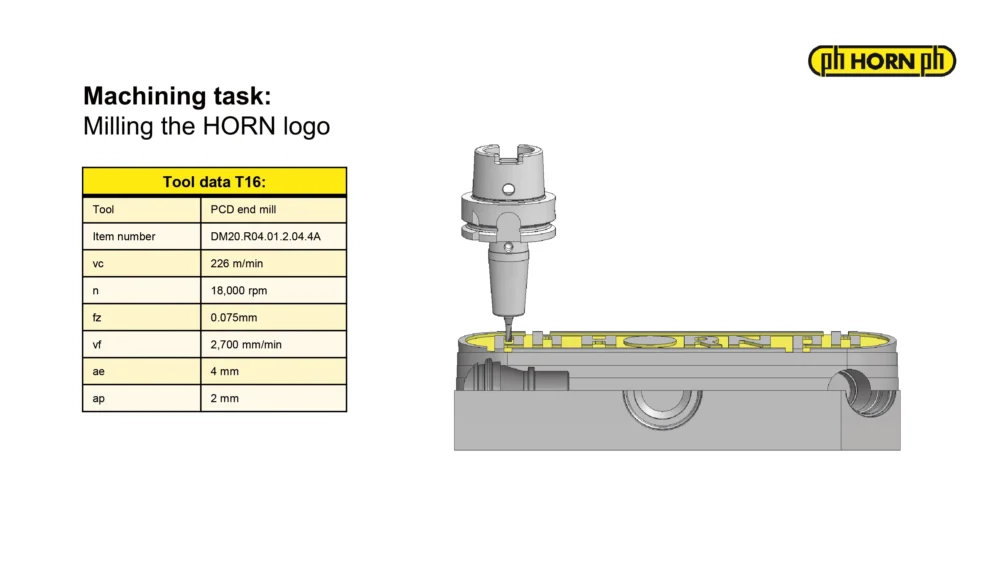

DM20

The PCD end mills in the DM20 series are universal all-rounders and are suitable for a wide range of applications. The double-edged PCD-tipped milling tools with centre cutting capability cover almost the entire range of machining applications and are universally suitable for non-ferrous metals and non-metallic materials such as engineering plastics. The series is rounded off by a specially adapted body design for dry or wet machining. Different PCD substrates as well as modern and customised technologies for cutting edge preparation ensure productive machining processes, as well as reliably high performance and a long tool life. With a semi-standard tool, HORN also offers the fast and flexible option of customisation to meet specific customer requirements.

The double-edged PCD-tipped milling tools in the DM20 series with centre cutting edge cover almost the entire range of machining applications.

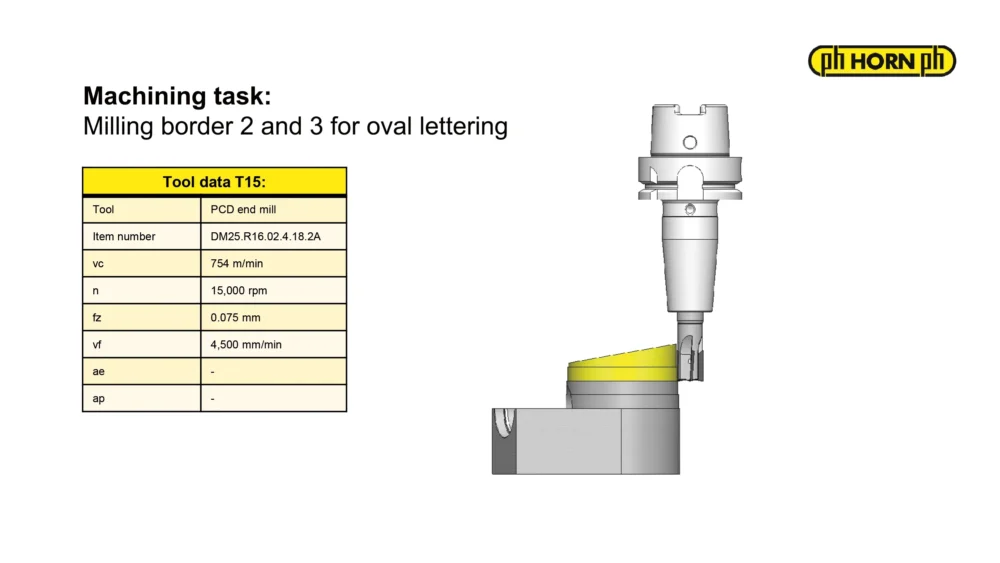

DM25

The DM25 product range with cutting edge lengths between 8 mm (0.314“) and 18 mm (0.708“) is particularly suitable for contour and finishing milling operations on external and internal contours when high cutting feed rates are required. The multi-edge design significantly reduces machining cycle times. While the R series with internal cooling is preferred for non-ferrous metals, the C series with an additional positive rake angle is suitable for machining abrasive materials through to graphite and fibre-reinforced plastics.

The DM25 product range is particularly suitable for contour and finish milling operations on external and internal contours when high cutting feed rates are required.

DM27

Modern fibre-reinforced composites are lighter, stronger and more stable – which is why they are becoming increasingly important for industrial applications. When machining these abrasive materials, the focus is on the quality of the component edges. Fraying, delamination or chipping create stringent criteria for tool geometry and grade in order to be able to control these component-specific and wear-related conditions. The risk of vibration on thin-walled components or when trim cutting panels, taking into account down or up milling options, represents an additional consideration for stable milling. With a positive-negative insert arrangement, coupled with internal cooling and a centre cut, the tools in the DM27 series offer a coordinated overall package for universal milling applications.

With a positive-negative insert arrangement, coupled with internal cooling and centre cutting, the tools in the DM27 series offer a coordinated overall package for universal milling applications.

DM30

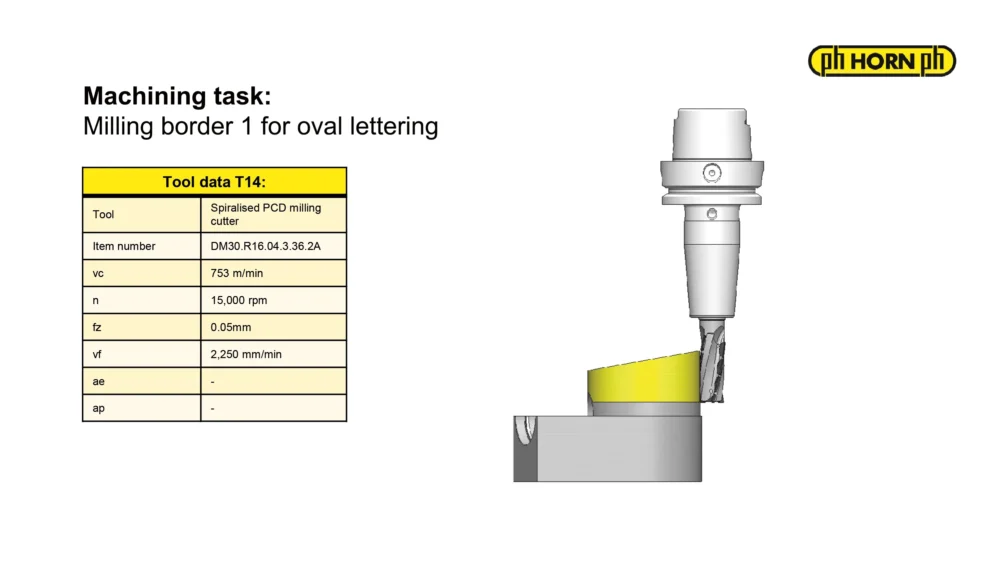

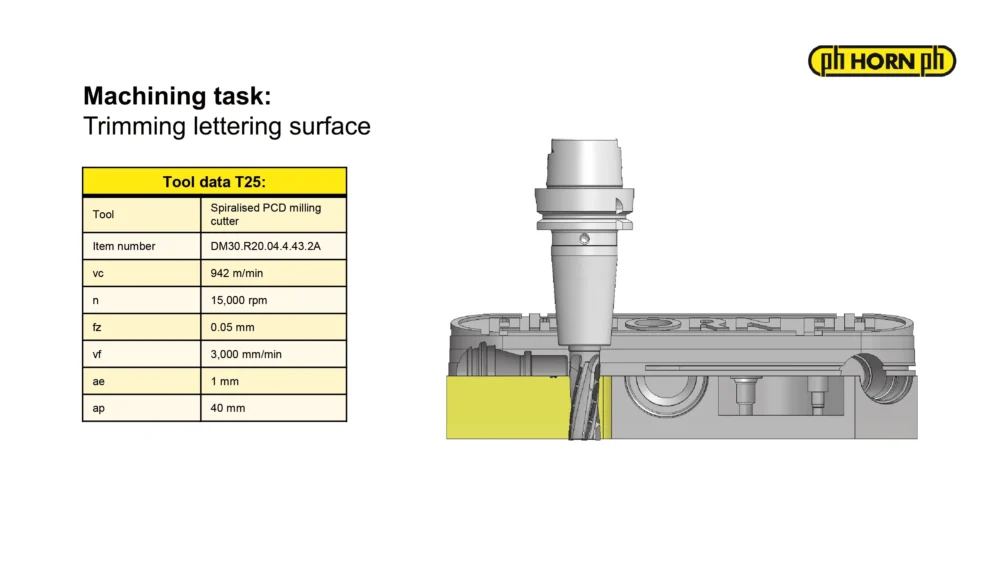

Milling tools in the DM30 series are specially designed for cutting tall components. The PCD-tipped milling tools in a spiral design impress with their smooth, paring cutting action . The segmented design reduces cutting forces and machining noise. The precise positioning and arrangement of the PCD inserts ensures high surface quality milling without burrs. The tools are suitable for peripheral milling, trimming or circular milling operations and can be used at small to medium infeed depths, as well as for finishing operations with maximum utilisation of the cutting edge length. The cutting edges are high quality and burr-free.

The milling tools in the DM30 series are specially designed for cutting tall components.

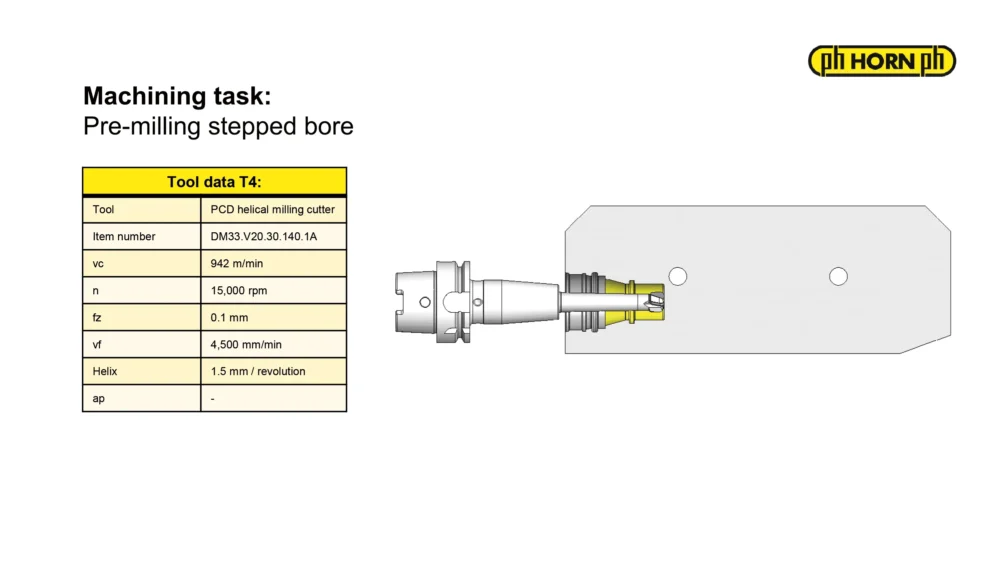

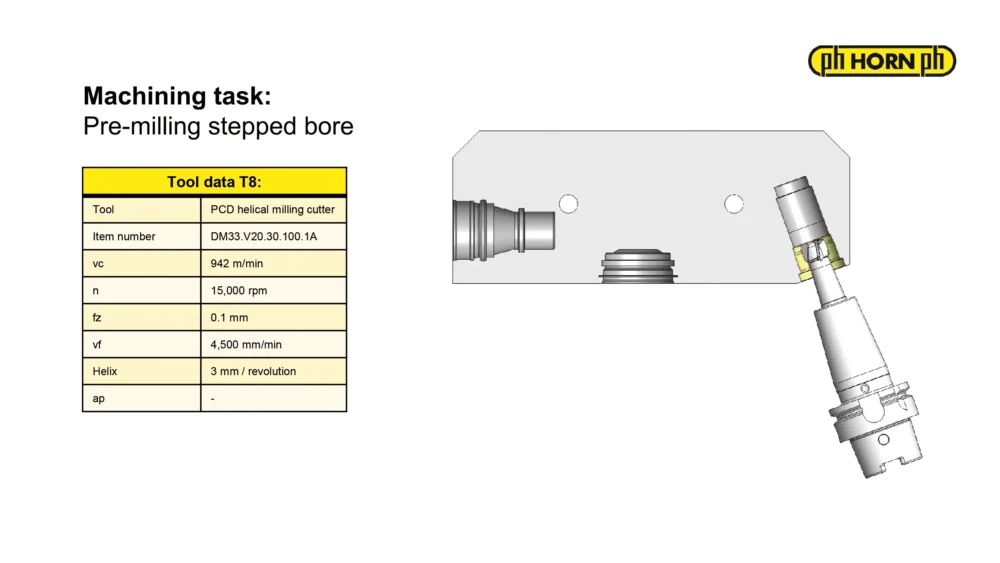

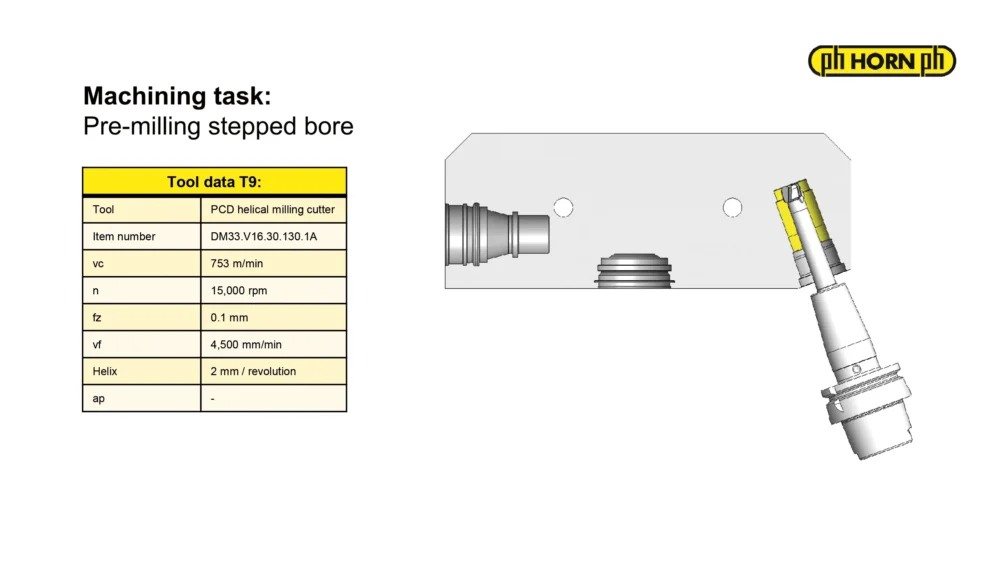

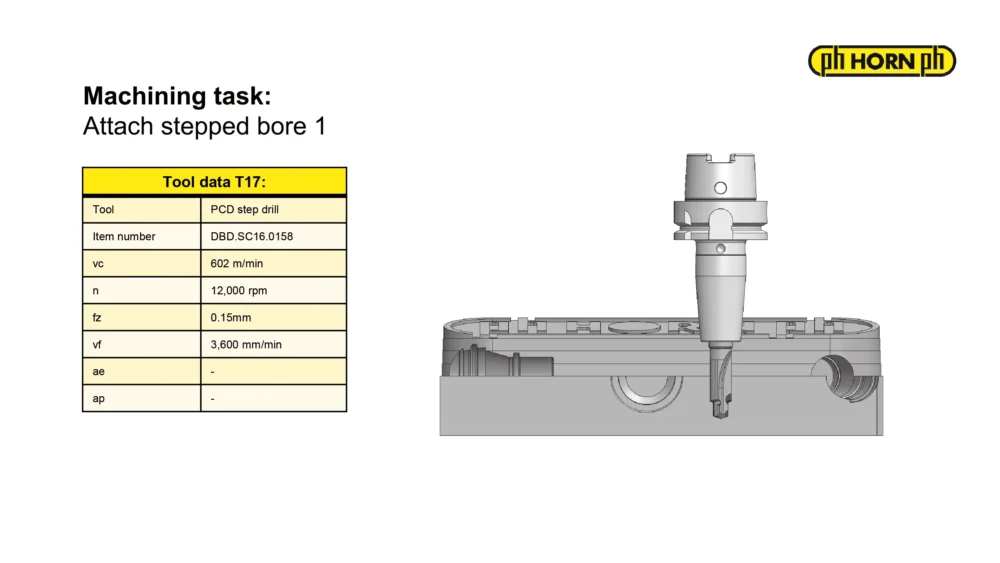

DM33

Components made from high-strength and forged aluminium are challenging to machine and place stringent demands on the tool. In contrast to classic aluminium die casting, extruded and forged aluminium causes long chip formation due to the lack of silicon and a compressed material structure. In addition, there are built-up edges and above-average stress on the tool. With the DM33 series, HORN offers a customised milling concept. Whether for face milling or ramping, the tools are designed to produce bores or pockets by helical entry into solid material without pre-machining and with high infeed values. Holes, cut-outs, pockets or profiles can be produced reliably and economically using tools of 12 mm (0.472“) to 16 mm (0.630“) and 20 mm (0.787“) diameter. The tools are designed with a central coolant channel and offer reliable chip flow even during deep machining operations. For larger bores, larger screw-in diameters are available in the DG-V series in conjunction with tool holders of various lengths.

This extensive expansion of the Horn portfolio in the area of ultra-hard cutting materials offers users the opportunity to obtain the appropriate, reliable tool solution for their machining applications. The focus is on cost-effectiveness and productivity combined with Horn technology, flexibility and reliability.

The DM33 series PCD milling cutter is a milling concept designed for applications where there is a tendency for the formation of built-up edges and for above-average stress on the tool.

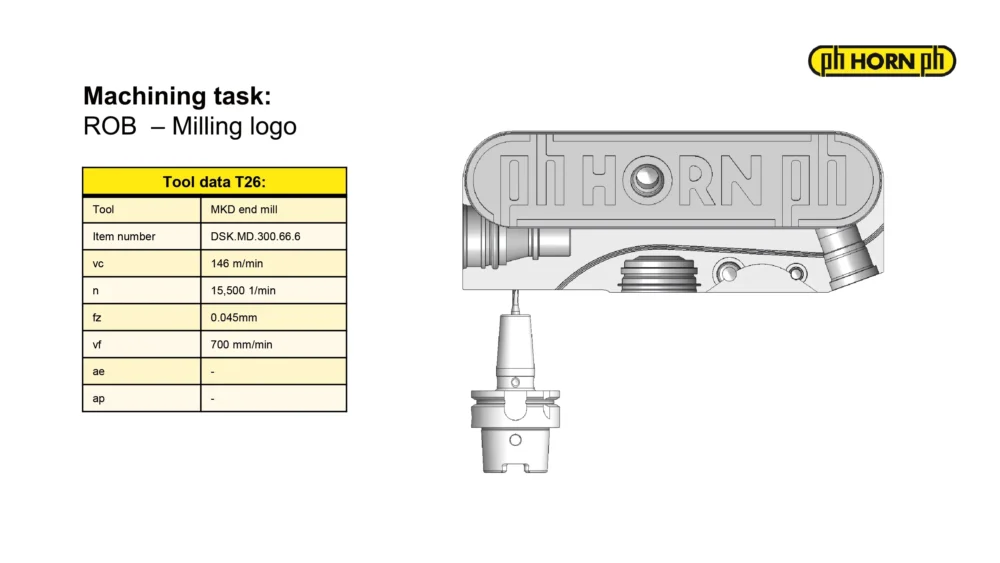

HORN HIGH PERFORMANCE MILLING – TECHNOLOGY COMPONENT

All process steps