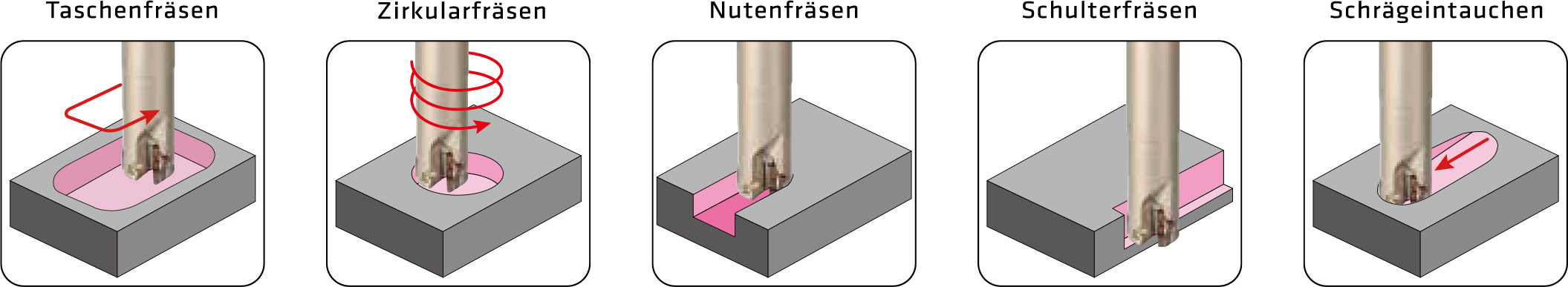

The WSE series is suitable for a wide range of applications, including structural parts made of titanium

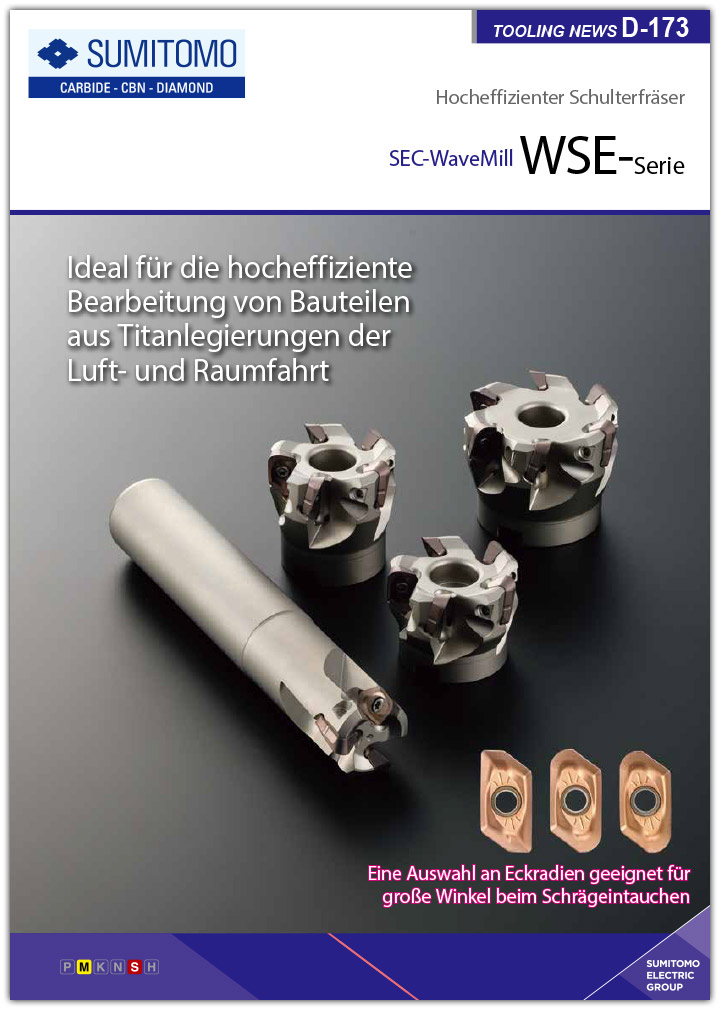

Ideal for high-efficiency machining of titanium alloys, such as aerospace components

Engineered for top-tier performance in titanium alloy machining, especially in the demanding aerospace industry, the WSE milling cutter is built for efficiency and durability. Here’s why it stands out:

Versatility

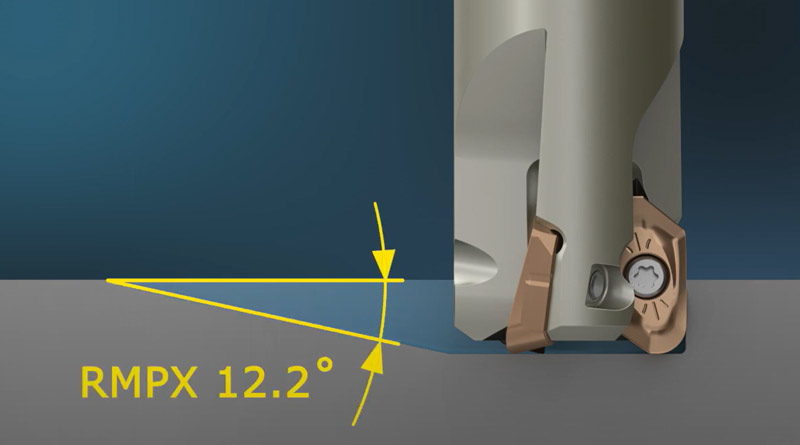

Ideal for machining large ramping angles and available with a range of corner radii, making it perfect for complex titanium structural parts.

Stability

SFeaturing the latest ACS2500/ACS3000 grades, this cutter provides superior wear and fracture resistance, even with exotic alloys.

Verbesserte Spanabfuhr

With an optimized cutting edge and chip pocket, the WSE ensures smooth and efficient chip flow, reducing downtime and boosting productivity.

A selection of corner radiuses capable of handling large ramping angles

- Carbide substrate with excellent wear and adhesion resistance, coupled with a chipping resistant coating, provide outstanding performance especially in machining titanium alloys

- High toughness carbide substrate and a coating with excellent chipping resistance provide outstanding stability when machining titanium alloys, heat- resistant alloys or stainless steel

Applicable to various applications!