Everything from a single source: revolutionise your gear manufacturing with tooling solutions from Horn and MT-Marchetti for lathes.

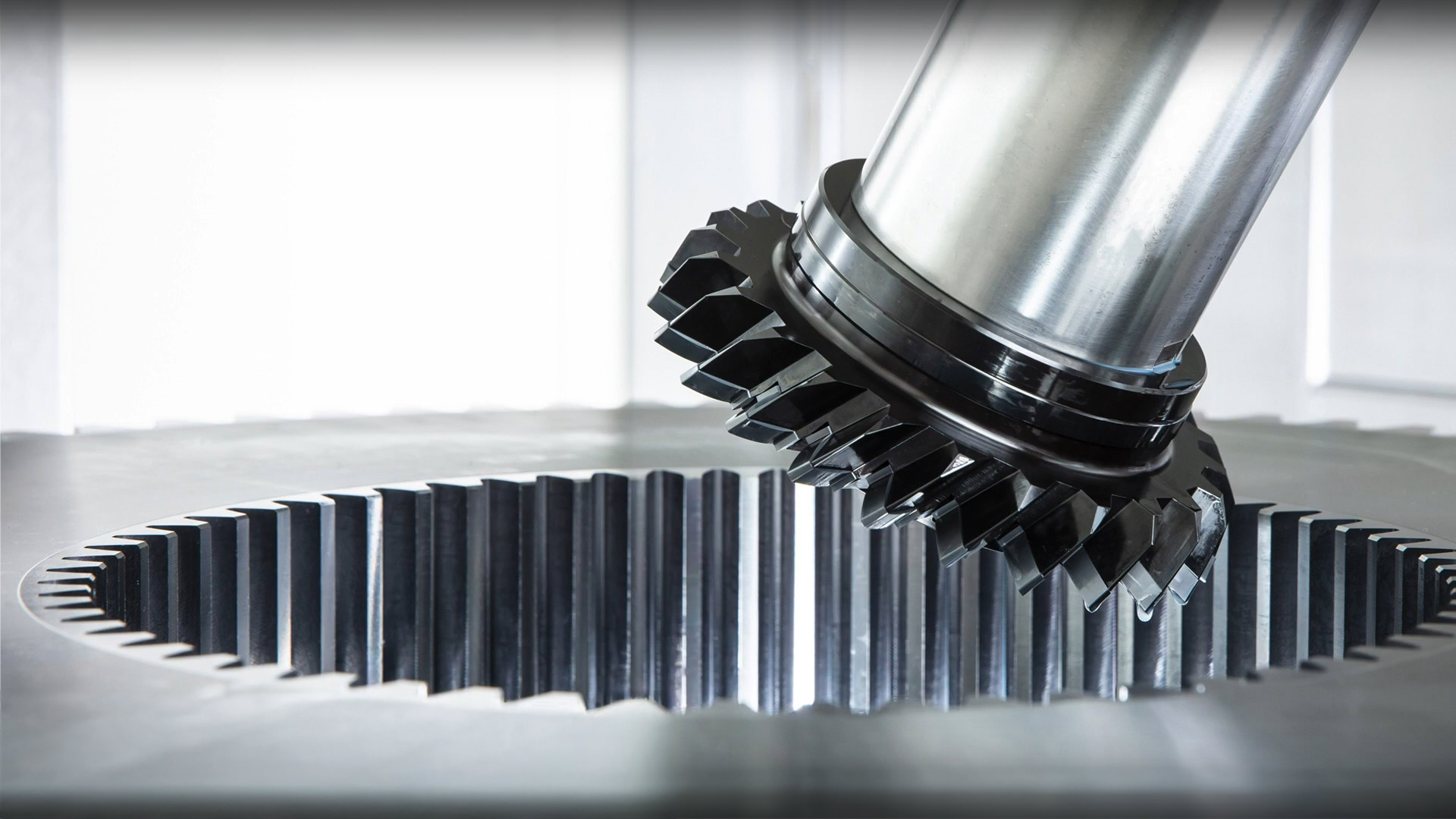

Power skiving, also called gear skiving, is one of the most exciting new processes in mechanical engineering. It is a continuous machining process that combines elements of turning and milling.

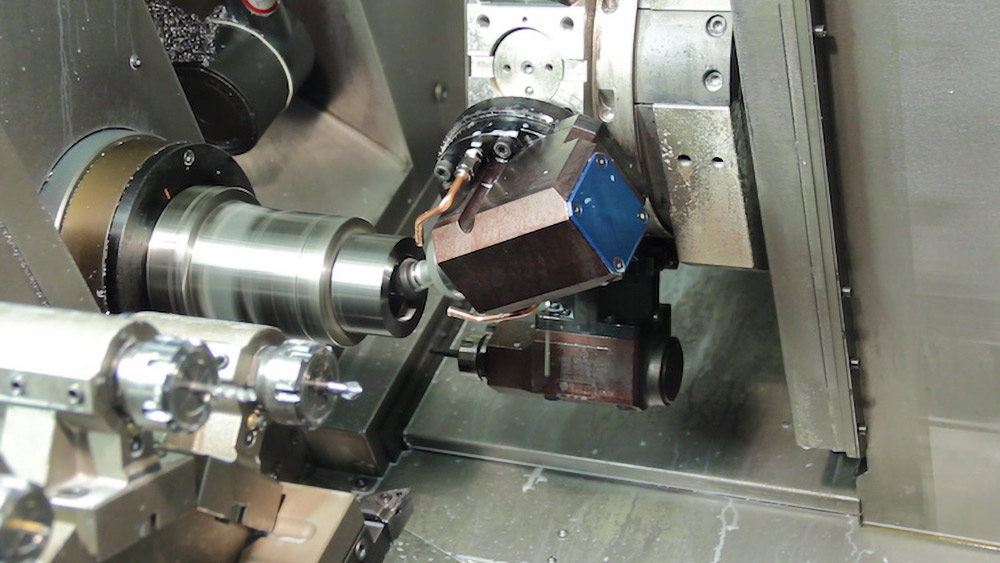

The tool and workpiece roll against each other at high speed and a defined cross-axis angle in order to precisely ‘peel’ the gear teeth out of the material. This innovative technology was patented over 100 years ago, but it is only now that modern, stable machines with precise spindle synchronisation have made it economically viable on a large scale. WEDCO now offers an outstanding complete solution for power skiving on lathes – with the combination of driven units from MT-Marchetti specially developed for power skiving and the powerful precision gear skving tools from HORN, you get a complete solution for maximum precision, productivity and cost-effectiveness.

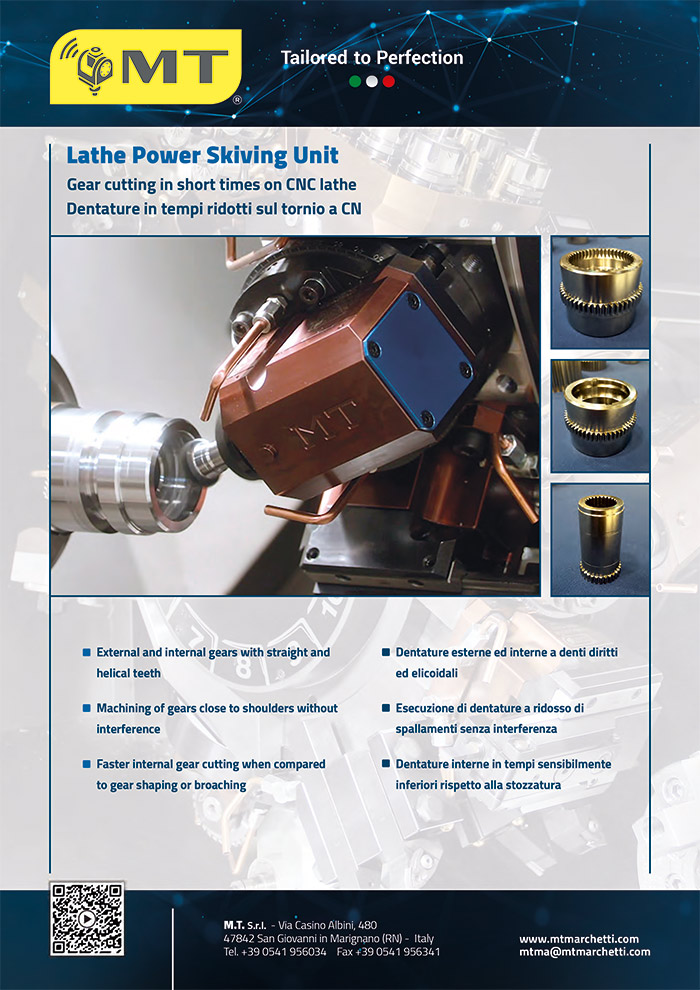

Internal gear teeth, external gear teeth and other gear teeth: the highly complex technology of power skiving can now also be implemented on universal lathes using MT Marchetti’s driven tool holders and special software. The system is suitable for producing different gear geometries. Whether external or internal gears, running gears or fitting gears, or even regular special shapes, all these tooth profiles can be produced extremely economically with these tools.

The advantages at a glance:

- Drastically reduced production times: Up to 50% time savings compared to traditional methods such as broaching or gear hobbing. Power skiving is up to three times faster than gear hobbing and 6 to 12 times more productive than broaching.

- Highest precision and quality: Achieve component quality absolutely comparable to other gear cutting processes. Machining in a single clamping prevents clamping errors and minimises concentricity errors.

- Maximum flexibility: Produce external and internal gears, both straight and helical, on the same machine. A particular advantage is the ability to work close to shoulders and interfering contours, giving you more freedom in component design.

- Increased efficiency: Reduce the number of machines required and lower your logistics and handling costs by combining multiple operations such as turning and gear cutting in a single machine.

Why power skiving with tools from MT Marchetti and Horn? The perfect synergy from a single source!

The success of power turning depends crucially on the perfect coordination between the machine, tool holder and tool. The process requires extremely rigid machine structures and tool carriers in order to withstand the rapidly changing cutting forces and prevent vibrations. With the driven tool holder from MT Marchetti, this can also be implemented on conventional lathes. Together with the high-precision tools from Horn, they form an unbeatable team that makes your production even more economical. This combination guarantees maximum process reliability, excellent tool life and optimum component quality.

Power-Skiving in a new dimension! The unique MT Marchetti power skiving tool

MT Marchetti is proud to offer a genuine innovation in gear cutting technology: the power skiving tool for CNC lathes with Y-axis. This groundbreaking technology enables gears to be produced in record time – 15 to 20 seconds instead of 6 to 7 minutes with conventional methods. MT is thus setting new standards in efficiency and productivity.

Versatility and precision

The tool allows the production of internal and external gear teeth, both straight and involute, even very close to a collar. Thanks to the innovative angle adjustment, working angles between 15° and 40° can be flexibly adjusted. With the MTSK quick-change system developed by MT, tools can also be changed quickly and precisely.

A real breakthrough in manufacturing

What was previously only possible on expensive special gear hobbing machines from a few manufacturers is now being brought to the CNC lathe for the first time by MT – after three years of intensive development work.

- Maximum rigidity

- Exact alignment (axle angle)

- High-precision bearing and drive

- Optimised for the stresses involved in power skiving

Comprehensive service from WEDCO

From the feasibility study to the selection of the optimum tools for gear skiving and machining parameters to the delivery of the driven tool holder: WEDCO provides its customers with comprehensive and reliable support throughout the entire process.

Successful applications in practical use

Companies in the planetary gear, automotive and packaging technology sectors are already successfully utilising this new technology. The results are impressive: maximum precision, excellent surface quality and drastically reduced machining times – comparable to state-of-the-art power skiving machines.

Power skiving with the MT Marchetti skiving unit on the CNC turning centre – fast, flexible, precise

The unique selling point and most important advantage of the MT Marchetti power skiving tool is that it no longer reserves power skiving for specialised gear cutting machines, but integrates it as a modular system on CNC turning centres — combined with high productivity, minimal machining times, flexibility and precise quality.

- Gear cutting directly on the CNC lathe

Unlike many power skiving solutions, which are implemented on specialised gear cutting machines, MT-Marchetti’s power skiving tool allows you to easily integrate gear skiving into your existing turning centre.

- Up to 90% shorter processing times

Internal and external gear cutting in seconds instead of minutes – maximum productivity with consistent precision.

- Flexible and versatile

Whether straight or helical teeth, internal or external, even close to shoulders – the power skiving tool from MT Marchetti offers maximum flexibility.

- Quick tool change

Thanks to the innovative MTSK system, you can change tools precisely and in record time – for shorter set-up times and higher availability.

- Highest precision and quality

Excellent concentricity and optimum rigidity guarantee perfect industrial-quality gear teeth.

- Easy retrofitting

Future-proof your existing machine – without high investments in separate gear cutting systems.

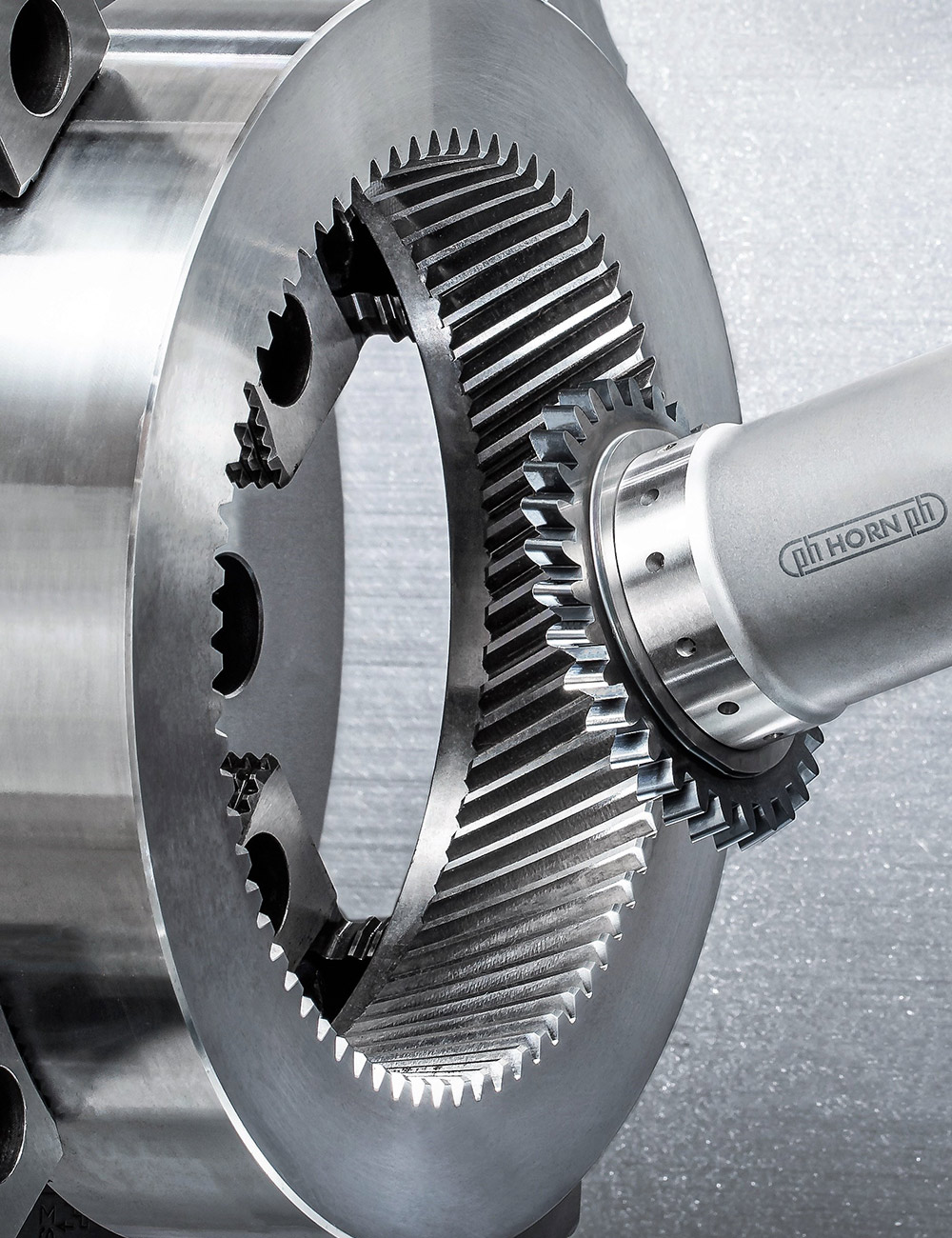

Mastering processes – with Horn’s gear skiving tools

The tool system includes tools for the highly productive manufacture of internal gear teeth, mating gear teeth and other internal profiles, as well as external gear teeth.

The tool system includes tools for the highly productive manufacture of internal gear teeth, mating gear teeth and other internal profiles, as well as external gear teeth.

The gear skiving tools are designed for machining of medium to large batches. Each tool is individually adapted to the application and the material to be machined, with the different tool interfaces based on the number of teeth and module size.

Horn demonstrates the advantage of short processing times with this process, particularly for internal gear teeth on larger modules. Large and rigid milling/turning centres are required for hobbing larger modules, as these enable the necessary synchronisation between the workpiece and tool spindles. The larger the module, the more critical the issue of machine rigidity becomes. This issue can be mitigated on the tool side by dividing the cut between the left and right flanks. Based on its experience with small solid carbide skiving tools, Horn used the expertise it had gained to cover larger modules as well. Before implementation, the technicians check the feasibility of each application and discuss the tool design and recommendations for the process with the user.

- Highly productive production of mating gears and other internal profiles as well as external gears.

- Key advantages: short processing times, use on suitable turning/milling centres, turning and gear cutting in a single clamping operation, and no need for clearance at the end of the gear teeth.

- Gear cutting of medium to large batches, whereby each tool is individually adapted to the application and the material to be machined.

- Short processing times, especially for internal gear teeth on larger modules.

- Large and rigid turning centres enable synchronisation between the workpiece and tool spindle for large modules.

- Discussion of tool design and recommendations for the process with the user, as well as verification of feasibility prior to implementation.

- Use of coupled and synchronised spindles and special software.

- Easy implementation of the process on conventional lathes.

- Economical production of different tooth profiles such as external or internal gear teeth.

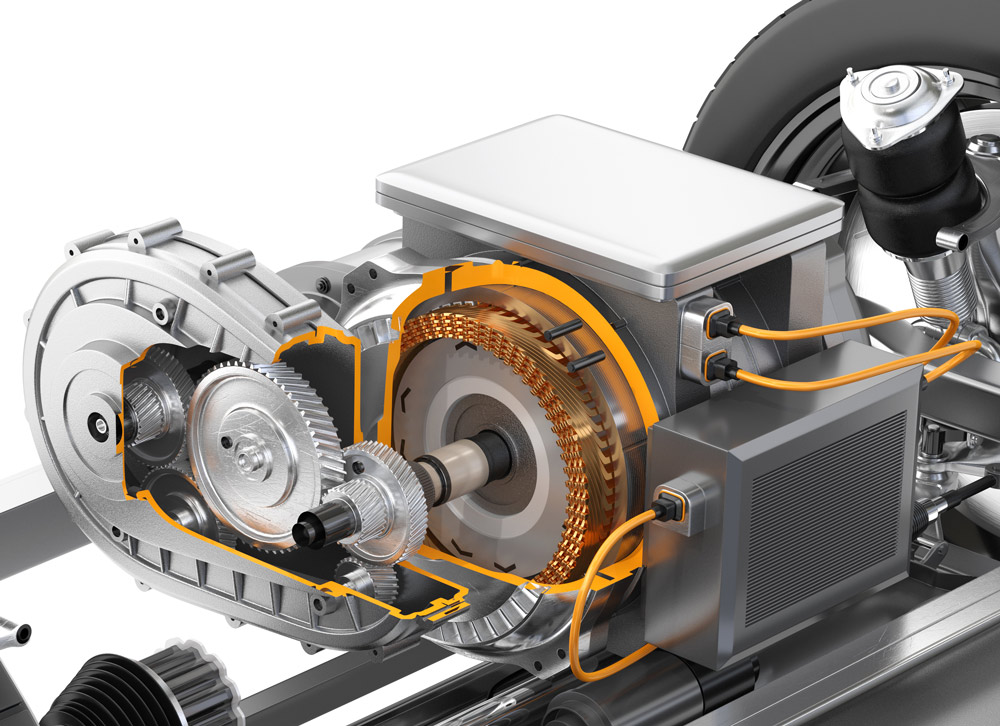

Application scenario: Power skiving as a key technology for electric car transmissions

Why is roll forming becoming increasingly interesting in electric car transmission manufacturing? The popularity of electric mobility is also changing transmission manufacturing. Since electric motors operate almost silently, transmission noise becomes more noticeable. This means that the highest standards of smooth running, dimensional accuracy and surface quality are required. At the same time, components must become more compact and lighter – especially in planetary gearboxes with thin-walled hollow wheels.

Was das Wälzschälen so attraktiv macht

Das Wälzschälen kombiniert die Vorteile von Wälzstoßen und Wälzfräsen in einem kontinuierlichen Bearbeitungsprozess. Dabei rotieren Werkzeug und Werkstück synchron, sodass die Zähne hochpräzise und in sehr kurzer Zeit erzeugt werden. Für die Getriebefertigung in der E-Mobilität ergeben sich daraus mehrere entscheidende Vorteile:

- Deutlich kürzere Zykluszeiten im Vergleich zu Räumen oder Stoßen

- Hohe Flexibilität bei der Herstellung von Innen- und Außenverzahnungen, gerade oder schräg

- Fertigung nahe an Schultern – selbst komplexe Geometrien lassen sich realisieren

- Geringere Stückkosten durch reduzierte Rüstzeiten und weniger Umspannvorgänge