Ideal for ultra-precise drilling and ultra-precise reaming: The latest innovation and addition to the Zero-Fit range is the NIKKEN Zero-Zero solution. It has been specially developed for lathes and CNC lathes that work with turrets..

Zero-Zero takes adjustment and avoidance of inaccuracies even further. The holder not only allows radial run-out adjustment, as with Zero-Fit, but also has a unique axial adjustment system that allows any misalignment between the centreline of the turret and that of the spindle axis to be fine-tuned too!

Main features:

- Radial und axial adjustment: .In addition to radial run-out correction, the system enables fine axial adjustment to optimise the alignment between the turret and spindle.

- Precise error correction: The combination of radial and axial adjustment can effectively minimise both concentricity errors and alignment errors, resulting in higher machining accuracy.

- Easy handling: The system is designed to be user-friendly and enables quick and precise adjustment directly on the machine.

The use of Zero-Zero holders makes it possible to significantly increase the precision of turning operations, extend the service life of the tools accordingly and significantly improve the surface quality of the finished parts. This innovation emphasises NIKKEN’s commitment to high-quality and reliable solutions in precision machining.

The integrated adjustment ring enables fine adjustment of the rotation error for optimum results.

Designed for increased precision and accuracy, NIKKEN’s Zero-Fit Solutions, guarantee sub-5µm run-out accuracy, even under demanding conditions where such precision was once considered unrealistic.

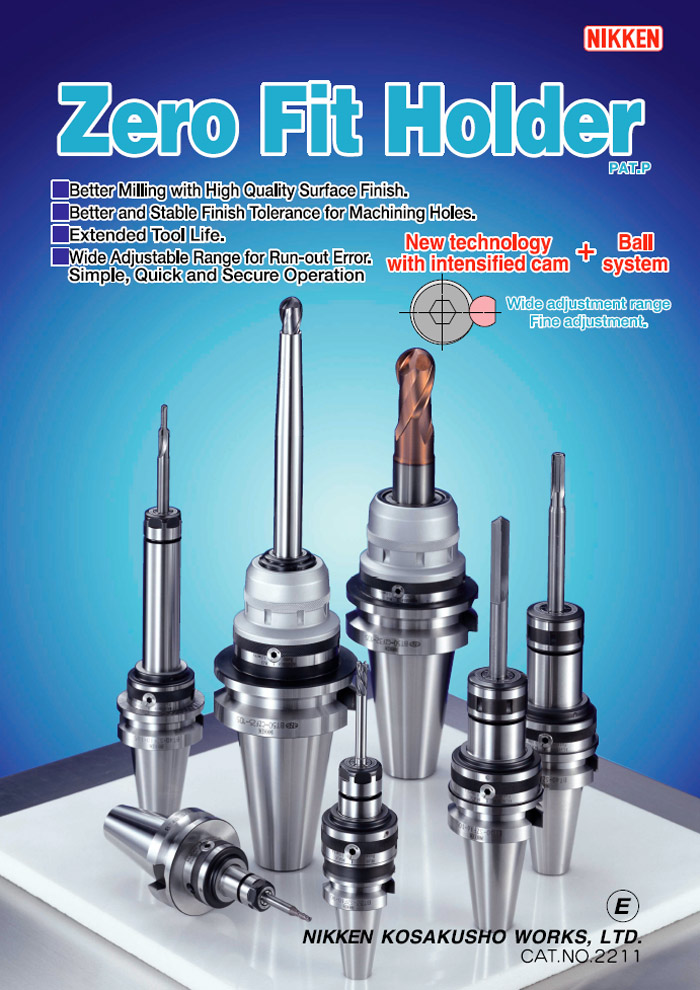

At extended lengths, achieving fine tolerances can become a serious challenge. However, NIKKEN’s Zero-Fit tool holders feature a uniquely designed adjustment system that is integrated seamlessly into the Multi-Lock Milling Chuck (CZF) and Slim Chuck 8-degree Collet Chuck (SZF). Both of these advanced tool holders are equipped with a highly precise adjustment ring featuring an internal cam system, which allows machinists to adjust tool rotation error, by up to 50 microns on diameter, with unparalleled accuracy.

The Zero-Fit technology is incredibly user-friendly: an operator can use a simple wrench to adjust the internal cam, which then “intensifies” or minimizes the run-out error (Zero-Fit is also available with a triple cam option to provide additional fine tuning). This adjustment process enables more efficient setups whilst providing lasting improvements in accuracy, minimized downtime due to tool wear and elimination of poor surface finishes.

NIKKEN’s standard tool holding solutions, depending on the combination selected, can guarantee and provide run-out at the cutting edge of three microns at four times the diameter of the cutter. This situation and capability provides optimum performance, reliability and tool life for any process or material.

However, if we consider such capability at a tool length outside these parameters or on an older machine spindle, an original accuracy of three microns is scaled and increased proportionally over any extended distance greater than four times diameter (of course the resulting error is considerably greater for less accurate solutions). The consequence of this situation, if not controlled, can be a detrimental decrease in both tool life and performance – a situation no one wants!

NIKKEN developed and introduced ZERO-FIT to counter this problem and allow the physical run-out at any length requirement to be precisely controlled and maintained. This control improves both the life of the tool and indeed the surface finish of the part or component.

The Zero-Fit solution is available across two of our market-leading tool holding solutions. The Multi-Lock Milling Chuck (CZF) and the Slim Chuck 8-degree Collet Chuck (SZF). Both feature a precisely balanced adjustment ring with an internal cam system which provides a physical adjustment of up to 50 microns on diameter. For the Multi-Lock the adjustment ring is mounted directly behind the nose ring which features an increased contact diameter and for the Slim Chuck, the ring is directly in front of the ‘V’ flange. Both systems function in exactly the same way: The initial run-out is measured, the cam ring is rotated to the point of maximum error and then the cam is advanced to reduce the measured value by half.

Zero-Fit is available with a single adjustment cam or, as an option, with a 3-point cam system. The 3-point solution provides a central ‘master cam’ for initial adjustment and then two additional cams to the left and right of the master for further fine adjustment of the accuracy (the 3-point option is not available for all Zero-Fit holders – please check for more information).

High-Performance Applications in Motorsport

In the motorsport industry, where every component must meet exceptionally high standards of precision, NIKKEN’s Zero-Fit technology has quickly become a game-changer. Motorsport teams demand parts with tight tolerances to ensure top performance under intense conditions, where even minor inaccuracies can impact vehicle speed, handling, and safety.

With Zero-Fit’s exacting control, engineers can now machine critical components such as engine parts, drive systems, and aerodynamic fittings with unparalleled accuracy. The solutions not only ensure optimal performance but also reduce the chance of operator error, provide an ability to hit tolerances first time every time whilst ultimately allowing the potential for reduced consumable costs related to premature tool wear! All key factors in motorsport manufacturing where speed and efficiency are paramount.

For motorsport manufacturers and precision engineers alike, NIKKEN’s Zero-Fit offers a vital tool for consistently achieving the highest standards in component quality.