REGRINDING SERVICE

Regrinding and reconditioning of used cutters and drills within the shortest possible time, in combination with the appropriate coating: with this service, we enable perfectly reconditioned cutters and drills with only minimal interruption to your production processes. Machining is carried out according to your grinding instructions, on state-of-the-art 5-axis CNC machines.

Easy and fast!

1. Collection of worn tools at the customers site by our pick-up service

2. Entering of the grinding order into our order processing system by barcode

3. Order confirmation by email

4. Regrinding on state of the art 5-axis CNC machines

5. Recoating with the original quality

6. Same quality tests and measurement checks as for new products

7. Labeling

8. Delivery to the customer at defined time intervals

PICK UP

Our free pick-up service is available throughout Austria and Hungary. It includes personal advice, order recording and collection of worn tools for regrinding and recoating. The tool taxi brings them to the Wedco Tool Competence Center as quickly as possible and delivers them with short delivery times.

REGRINDING

At the end of their service life, many solid carbide tools have by no means reached the end of their total life. On original production machines, the original geometries are restored in original quality, thus decisively extending their service life. The tools that are reconditioned with our 100% original grinding achieve almost 100% of their service life. They can usually be reground up to 3 times and thus realise their potential much more effectively, as the result is savings of up to 50% in tool costs.

COATING

Our tools come with exactly the coating most suitable for your application. We only work with long-term partners with convincing quality and professionalism. Thus, it´s assured that the regrinded tools will have the same coating as for initial delivery.

Find out more about the WEDCO regrinding service for your tools here!

request service prices here

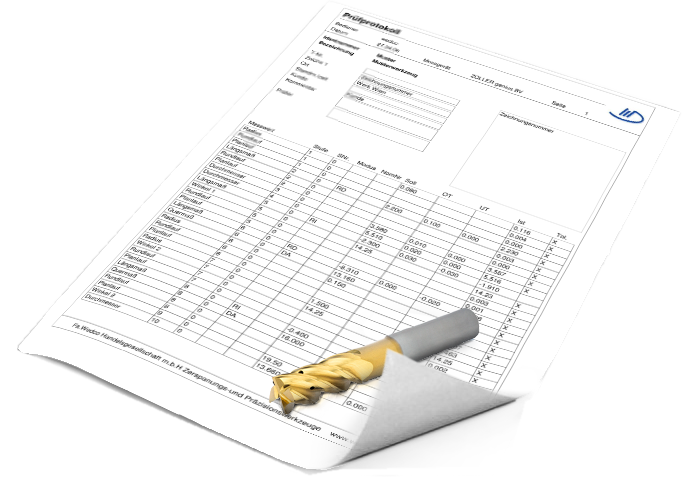

Measurement protocol

On request, we can provide you with measurement protocols as proof of the high-quality standards of our tool production and reconditioning service. Our high-precision measuring machines perform a wide range of measured values, such as: diameter, concentricity, corner radii, step lengths, cone and chamfer angles, rake angles, clearance angles and chamfer widths on the forehead and circumference as well as contours of all kinds in tolerance band adjustment. All relevant data are listed in the measurement report and can be sent electronically or by printout.

Measurement report as a proof of quality for reconditioned solid carbide milling cutters and drills