Sooner or later, every user, purchaser or production manager is faced with the question: throw away (better: recycle) worn tools, or have them reconditioned? Does it pay off compared to buying new or not? And how much effort does it mean for me (packaging, shipping…)? It’s a good thing that the WEDCO 100% regrinding service answers these questions quickly and reliably.

Regrinding of cutting tools offers a lot of potential to save costs. Nevertheless, this possibility is not used nearly as often as it could be. Many rumours are circulating in internet forums, but it can be quite simple: Ask the professional and you are sure to make the right decision.

The WEDCO 100% regrinding service – so it certainly pays to reprocess your tools.

Davor Zovkic, Product manager for Service at WEDCO:

- “With our regrinding service, you can ensure that your tools are always in optimal condition and that you can achieve the best possible work results. Trust in our experience and know-how, we will be happy to advise you without obligation.”

Why a timely, professional regrinding service is important?

- The regrinding service enables optimum performance and service life of your tools . A dull tool not only leads to poor work results, but also to unnecessary stress on the tool and the processing machine.

When is it time to have your tools regrinded?

- If you notice that your tools no longer deliver the desired precision and surface quality, then it is most likely time for the regrinding service. Increased vibrations or increased wear are also signs that a regrinding service may be necessary.

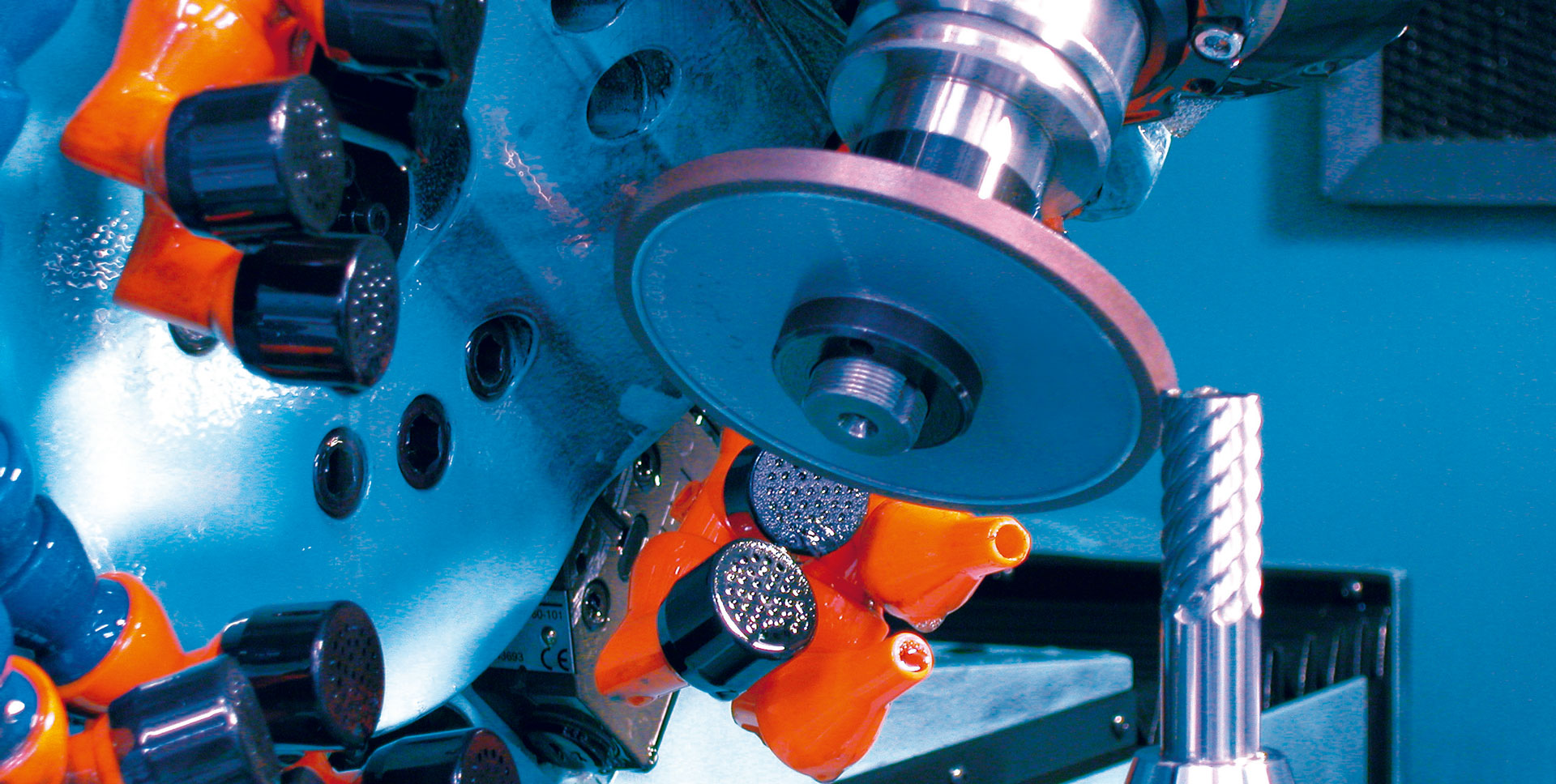

How does WEDCO regrind your tools?

- Our experienced and qualified team carries out the regrinding service on the same modern 5-axis machining centres that are used in new tool production. In the process, each tool is individually checked and, depending on requirements, regrinded and recoated.

What advantages does our regrinding service offer you?

- Optimum performance over the entire life of your tools

- Reduction of tool costs by utilising the actual service life of your tools

- Work results in constant quality

- Reduced load for tools and processing machines

- Individual assessment and transparent, non-binding cost breakdown

- The tools are reground on state-of-the-art 5-axis machining centres, with the original cutting data (original cutting data are only available for WEDCO tools)

- Recoating in original quality (original coating is only available for WEDCO tools)

We advise you competently and inform you in advance about the costs. Thus you get a clear basis for deciding whether the respective tool should be reconditioned or not. Because at the end of the day, it’s the bottom line that counts. An enquiry to our professionals is therefore always a gain and more informative than any internet forum.

WEDCO is a pioneer when it comes to regrinding cutting tools. After all, this has been one of the central services of our company since its foundation. That’s why you can rely on us to ensure that every regrinding job pays off 100% for you.

- 100% Price guarantee: We inform you exactly about the costs of your request, so you have the quick and accurate price comparison to the new purchase and avoid the risk of unprofitable regrinding.

- 100% Quality: At WEDCO, your tools are reground on the same machining centres that are used in new production, with the same geometries and, if desired, with the same coating from the same coating plant..

- 100% Service: Our Tool Taxi (in Austria and Hungary) collects the tools from you and delivers them again after the service, free of charge. We also provide you with the packaging.

DOES THE REGRINDING SERVICE PAY OFF FOR ME?

This question can be answered simply: We calculate it for you – just ask us!

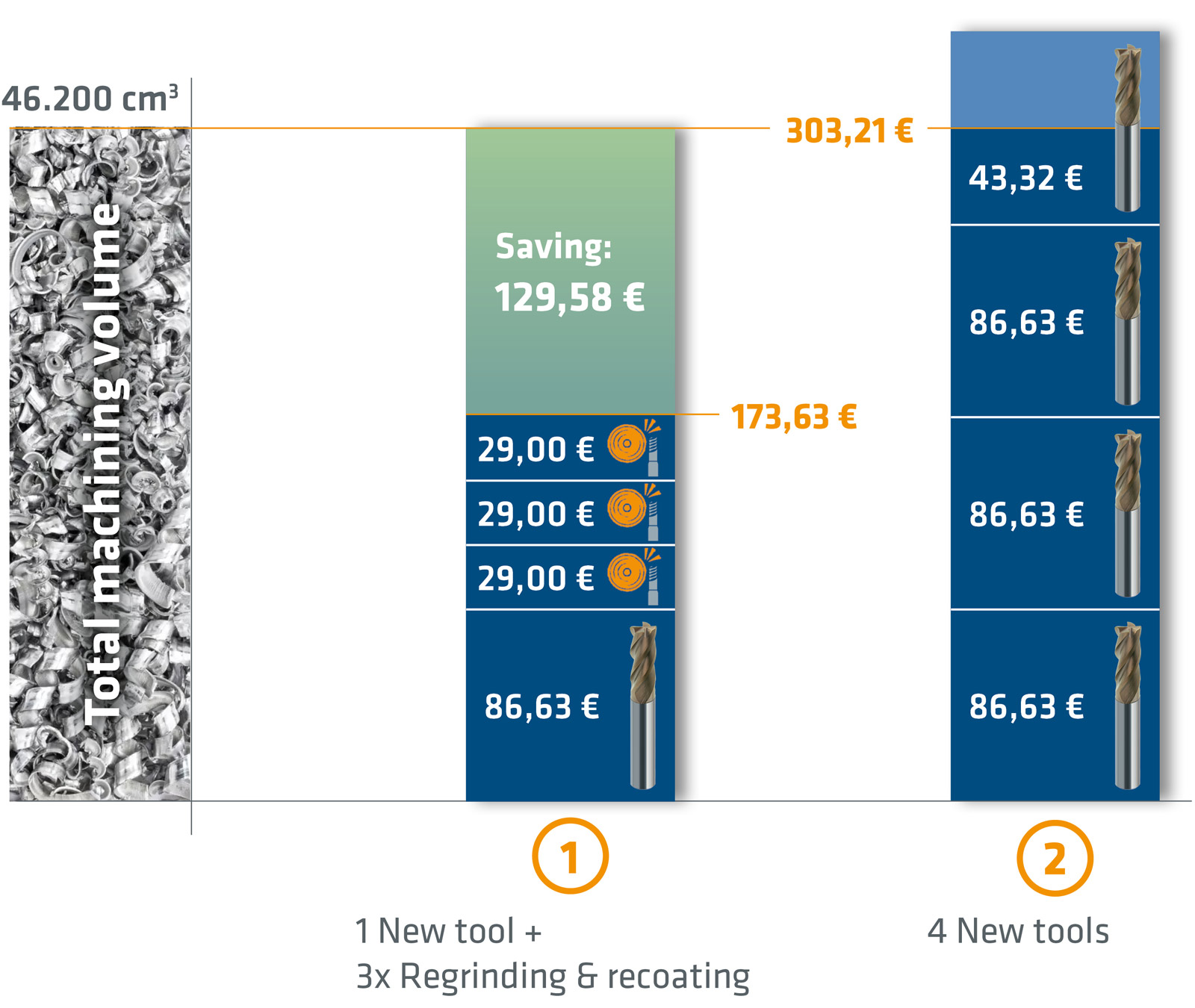

Illustration

Comparison of reconditioning vs. buying a new tool using the example of our end mill FLWX084 12004 under realistic conditions. For the calculation, we have used the current list prices for tools and service (circumference and face grinding, coating). We have assumed three times reprocessing.

Parameters

Tool: FLWX084 12004

Ø: 12 mm (Diameter)

Z: 4 (Number of teeth)

ap: 20 mm (Cutting depth)

ae: 4 mm (Arbeitseingriff)

Vc: 130 m/min (Cutting speed

fz: 0,1 mm (Feed/tooth)

1 new tool + 3x regrinding173,63€

1 new tool + 3x regrinding173,63€

The tool was reground 3 times and recoated. Overall, the tool thus achieves a total machining volume of approx. 46.200 cm³.

Machining volume:

- New tool: 13.200 cm³

- after 1st regrinding: 11.000 cm³

- after 2nd regrinding: 11.000 cm³

- after 3rd regrinding: 11.000 cm³

- Total machining volume: 46.200 cm³

3,5 New tools 303,21€

3,5 New tools 303,21€

In order to compare the costs objectively, the same machining volume of 46,200 cm³ was used. This requires the use of 3.5 new tools.

Machining volume:

- 1st New tool: 13.200 cm³

- 2nd New tool: 13.200 cm³

- 3rd New tool: 13.200 cm³

- 4th New tool: 6.600 cm³ (after half of the service life)

- Total machining volume: 46.200 cm³

HOW DOES A REGRINDING SERVICE WORK?

- After you have informed yourself about the prices in writing or by telephone, you give us the collection order

- Our Pick Up-service collects the worn down mills and drills to be reconditioned from you free of charge

- We record the regrinding order in the order processing system by barcode, you receive an order confirmation by e-mail

- Your tools are reground on state-of-the-art 5-axis CNC machines

- At our coating professional, the tools receive a new coating in original quality

- For quality assurance, the reprocessed tools are checked at the measuring stations

- Marking and labelling

- The tools are delivered to you again at the agreed time