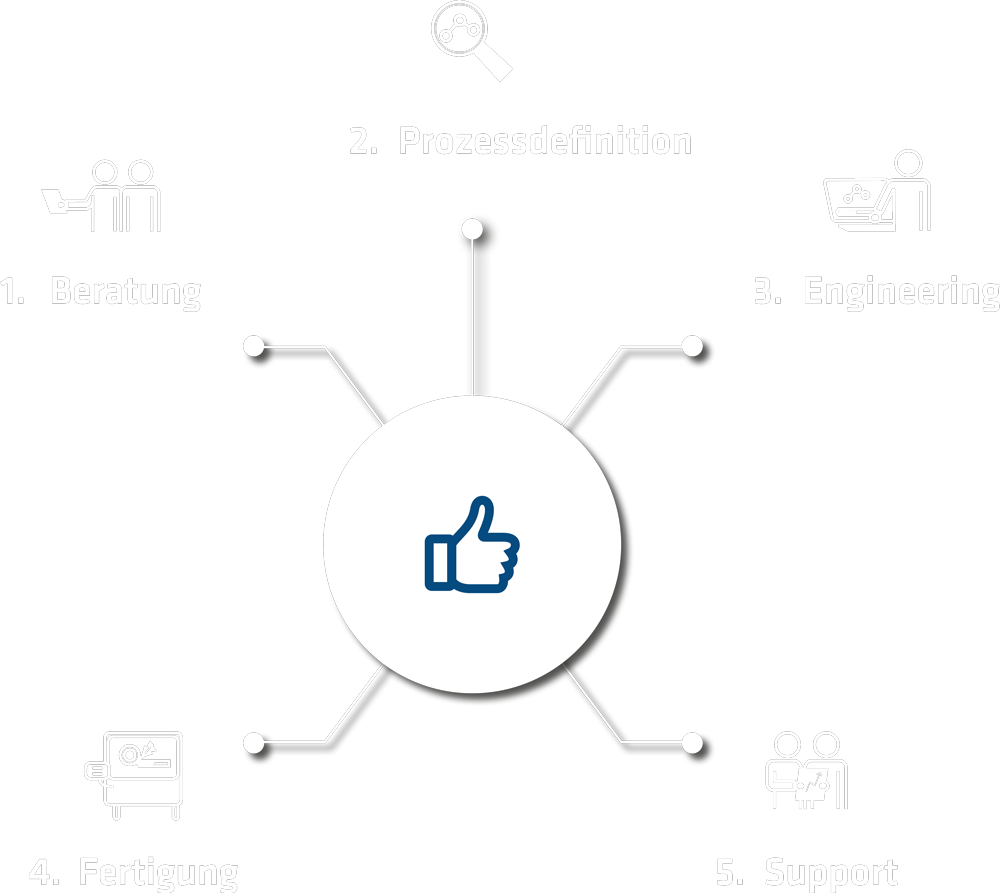

1. Beratung

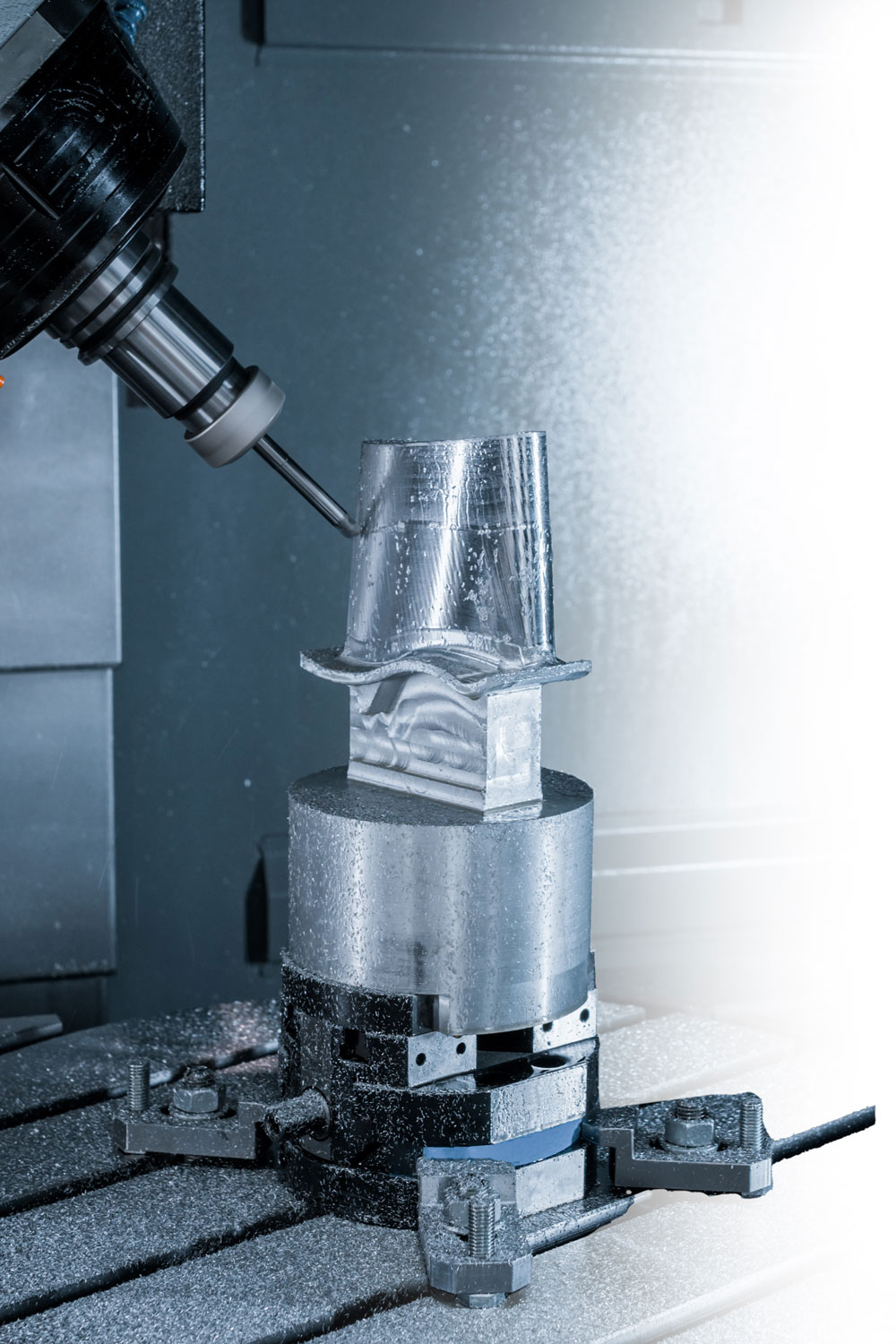

Ihre Produktion im Fokus

Sie möchten das Potenzial moderner Zerspanungstechnologie optimal nutzen? Es gibt zahlreiche Möglichkeiten – wir unterstützen Sie dabei, die besten für Sie zu finden.

Optimale Bearbeitungsstrategie

Sie suchen die optimale Bearbeitungsstrategie für Ihren Bauteil? Wir erstellen für Sie einen maßgeschneiderten Bearbeitungsvorschlag inklusive der idealen Werkzeugwahl.

Konkreter Anwendungsfall

Sie haben bereits eine Vorstellung vom passenden Werkzeug? Perfekt, wir geben wertvolle Tipps, setzen Ihre Idee um und fertigen Ihr individuelles Wunschwerkzeug.

Aktuelle Produktionsstrategie überdenken

Sie möchten Ihre aktuelle Produktionsstrategie „Out of the Box“ neu denken, um Kosten zu senken? Wir entwickeln innovative Lösungen, mit denen Sie Ihren Bauteil effizienter und kostengünstiger fertigen können.

Ihr Vorteil?

Eine Partnerschaft auf Augenhöhe! Profitieren Sie von unserem Fachwissen und sparen Sie wertvolle Ressourcen. Betrachten Sie uns als Teil Ihres Teams – kostenlos, transparent und unverbindlich.

Unser Ziel?

Ihr verlässlicher Technologiepartner zu sein! Wir möchten die Ersten sein, an die Sie bei Fragen zur Zerspanung denken. Ihr nachhaltiger Erfolg ist auch unser Erfolg.