24.08.2020

Increase productivity? We have what it takes!

KWFL Ball-nosed end mills

The constantly increasing challenges when it comes to materials and machining strategies on the market when machining steels up to 52HR lead to ever higher standards and require the constant further development of solid carbide tools at Wedco.

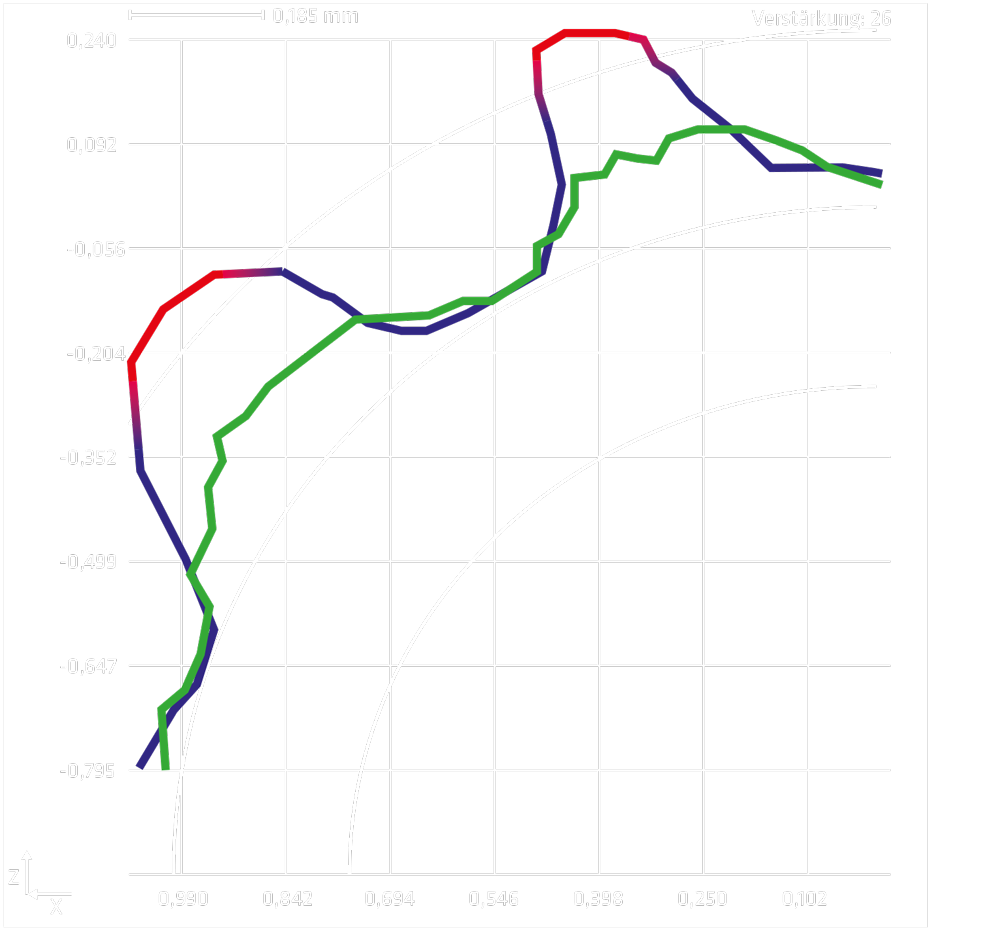

Extensive benchmark tests have been carried out in the Wedco HQ application center with various materials over the past 12 months, e.g. 1.2316 (M303), with our own tools as well as competitor tools.

The newly developed KWFL-milling cutter series from our Premium linet contains solid carbide ball-nosed end mills for soft machining up to 52HRC, for roughing and high-precision finishing.

Improved chip evacuation and increased stability of the tools due to the optimized cutting edge geometry

Various cooling options such as dry, wet, MQL and cooling with cold air are possible without decomposing the coating prematurely thanks to new coating technology.

The advantages of this coating are: higher density, finer structure and smoother surface than conventional multilayer systems, resulting in an improved service life.

Applying the WEDCO VSO process micro-tips that are created by the grinding process on the cutting edge, are smoothed and homogenized, what results in a more stable cutting wedge and generates a more homogeneous structure. The result is an increased cutting edge stability as the cutting edge has a defined radius, providing a stable base to the coating, so that all of its advantages can be exploited.

The VSO treatment also minimizes edge and micro breakouts. Reduction of the coefficient of friction in the area of the cutting zone and the groove also promotes better chip evacuation.

All of these individual improvements add up, enabling a significantly longer tool life and enormously increasing process reliability in the milling process.