21.04.2020

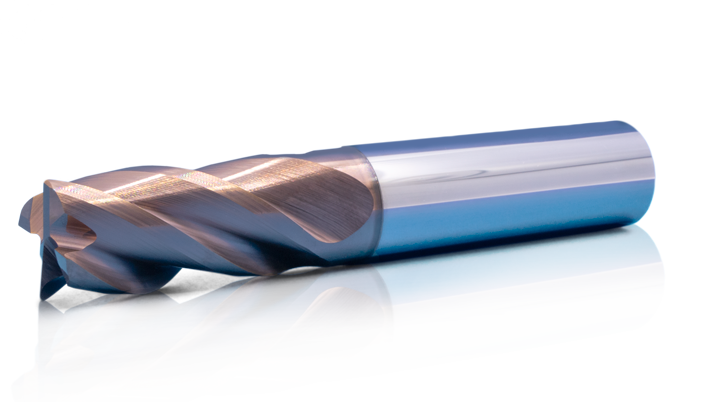

Solid carbide end mills

for general steel machining up to 54 HRC

To constantly meet the challenges of the market, even in difficult times like at present, and to always be able to offer the most appropriate tools, even to very demanding machining tasks, we continuously work on refining our products and technologies. As one result of our permanent research work, an all-new milling cutter series was developed for machining steels and high chromium steels, which promises significant improvement in performance and tool life. These so called FLWX – milling cutters are designed for rough machining and finishing of steels up to 54 HRC.

Due to its good chip assimilation qualities and the optimized usage of the cutting contour, processes can be optimized on both counts, technically and economically. The new cutting geometry allows both, full slot roughing and entirely new milling strategies such as trochoidal cycles with high feed rates and cutting speeds.

Examples of use

FLWX093 16004 (Ø16)

Roughing in 1.2316 (Cr 16,5%)

- ae=4 mm

- ap=20 mm

- vc=140 m/min

- fz=0,1 mm

- Improvement in service live compared to competitors: +37%

FLWX093 16004 (Ø16)

Roughing in 1.4404

- ae=12 mm

- ap=18 mm

- vc=140 m/min

- fz=0,06 mm

- Improvement in service live compared to competitors: +42%